Sensors&Printed Electronics

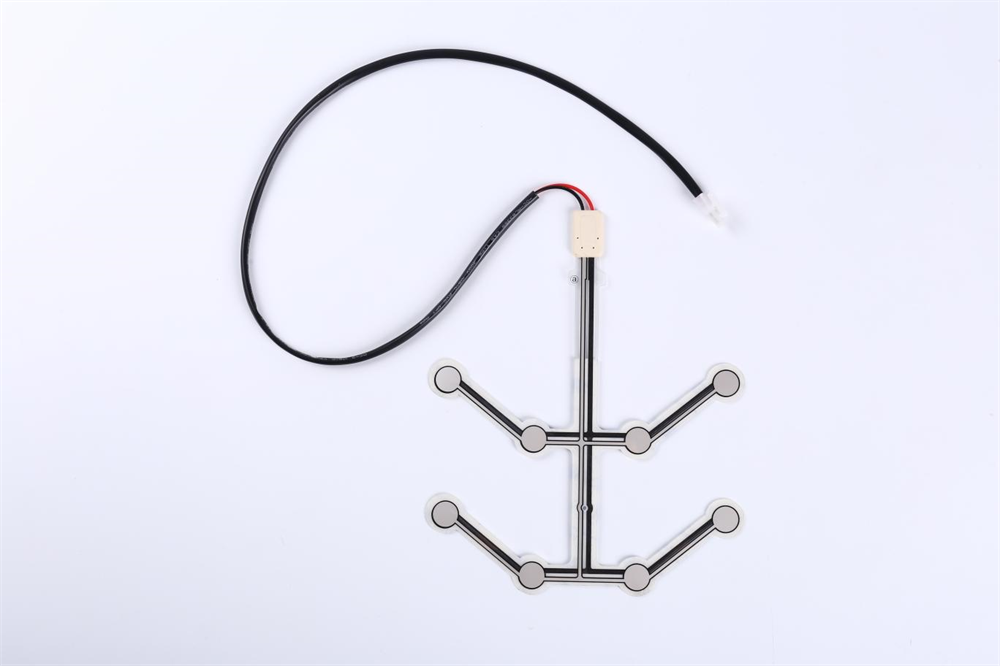

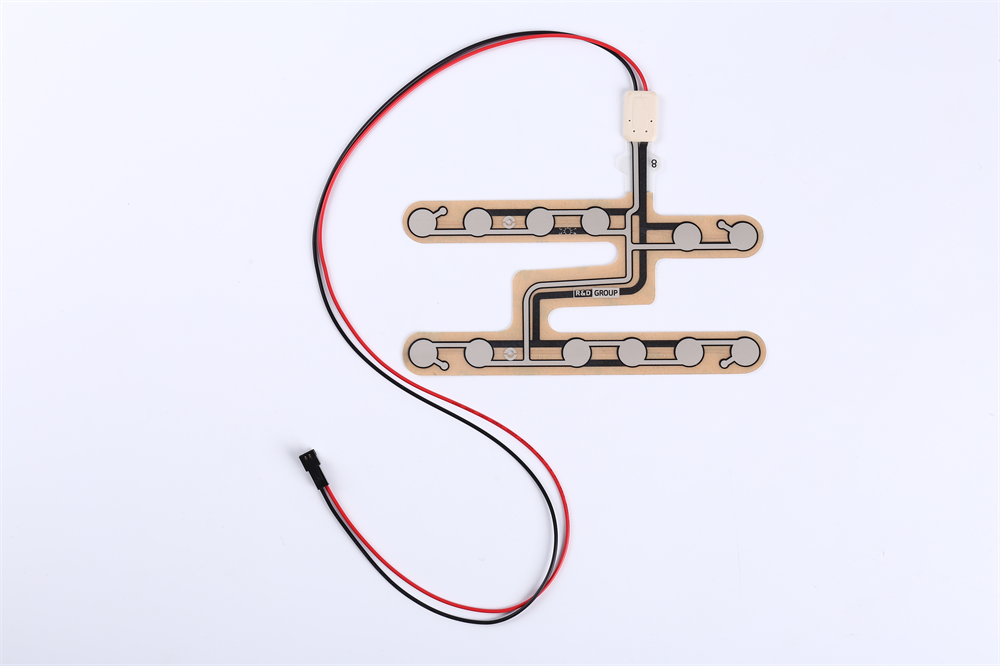

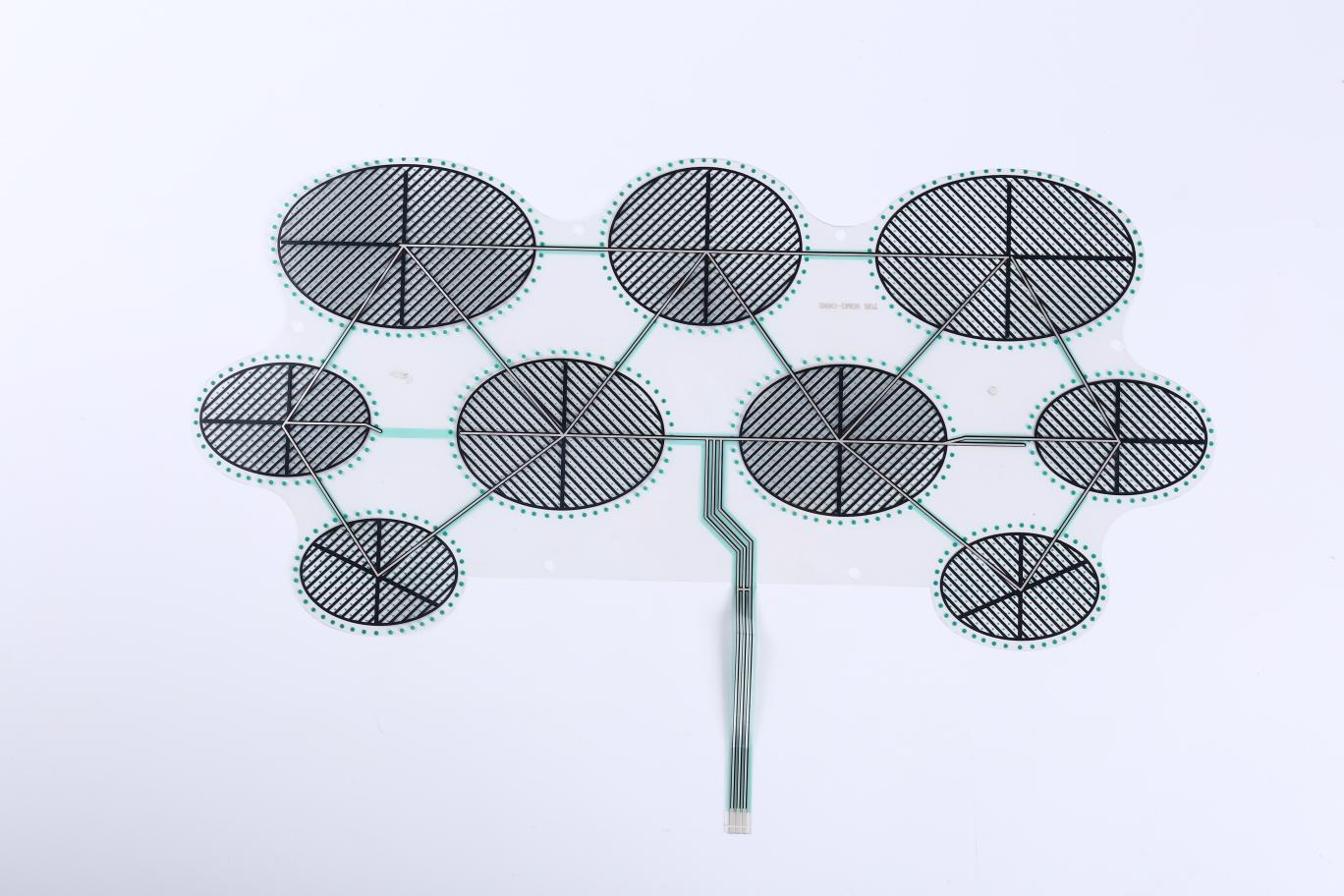

Thin film pressure sensors are sensors based on thin film materials, and their main function is to measure the pressure applied by an object on its surface. They are usually composed of a thin film, a base, and a conductive layer, and their working principle is based on the change in resistance of the thin film material when it is subjected to force. In short, thin film pressure sensors are flexible and versatile sensors that are suitable for a variety of different application scenarios, thus providing solutions for pressure measurement and touch detection.

Working Principle The working principle of thin film pressure sensors is based on the change in the electrical potential of thin film materials when they are subjected to force. These sensors are usually composed of a thin film, a conductive layer, and a supporting base. The following is an overview of the basic working principle of thin film pressure sensors:

Application characteristics

Thin film sensors provide information about pressure levels by monitoring the tiny deformation of thin film materials when they are subjected to force, which is converted into changes in resistance. Here are some of the main applications of thin film pressure sensors:

1. Touch sensing: can be used to detect and measure touch and press. This application is common in devices such as touch screens, electronic keyboards, digital buttons, etc.

2. Force measurement: can measure the amount of force applied to the surface of an object. In industrial, manufacturing and laboratory environments, they can be used to monitor the force on machines and equipment and trigger corresponding actions when needed.

3. Medical equipment: widely used in the medical field, such as making wearable devices, bed monitoring systems or other medical devices to measure the pressure distribution, posture and movement of patients.

4. Automotive industry: In automotive manufacturing, thin film pressure sensors are used to monitor the position and weight distribution of passengers on seats to better control the deployment of airbags.

5. Industrial automation: In industrial environments, these sensors can be used to monitor the pressure, force or touch status of equipment to achieve automated control and monitoring of production processes.

6. Robotics: can be used for touch perception of robot hands or fingers, allowing robots to interact with the surrounding environment more sensitively.

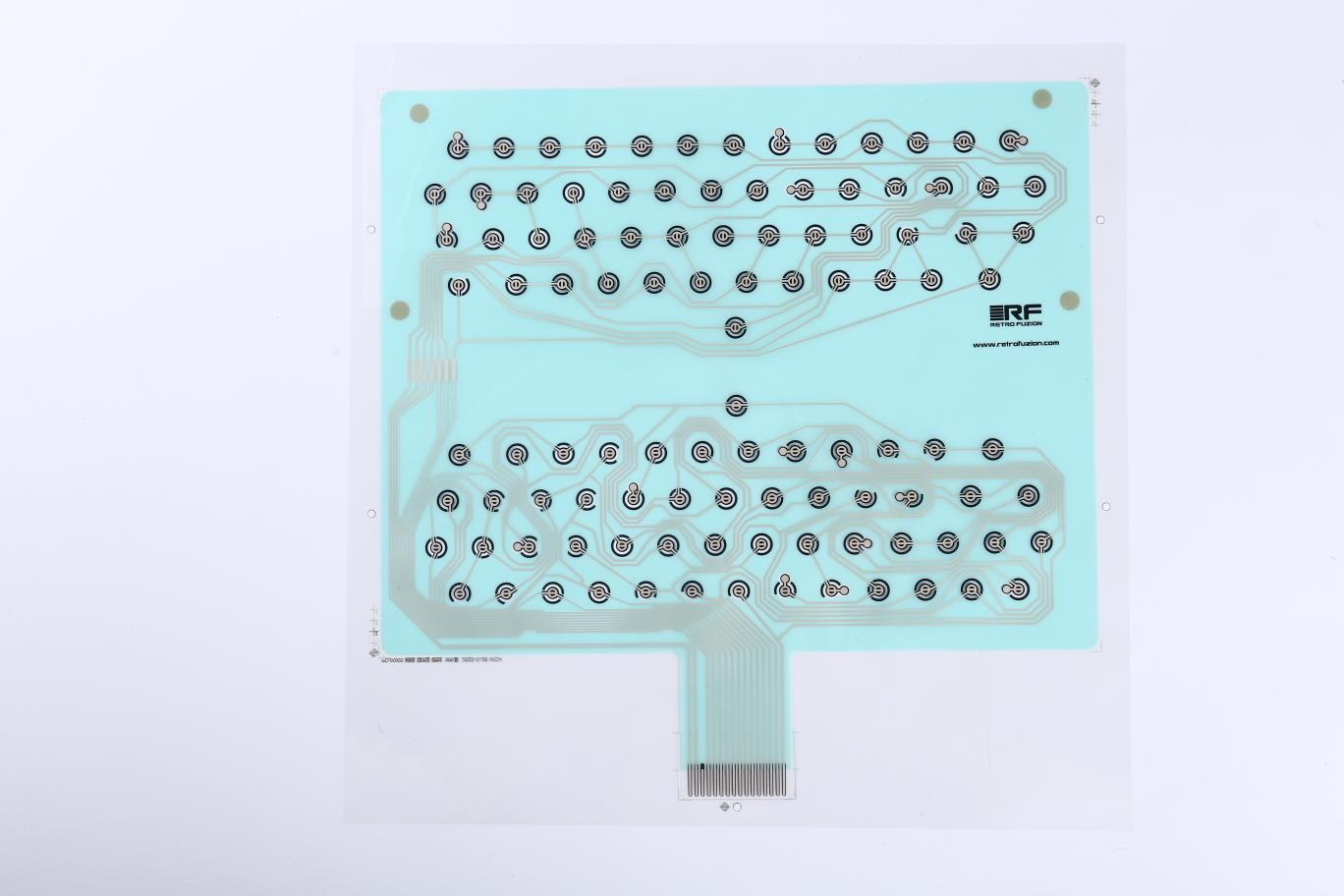

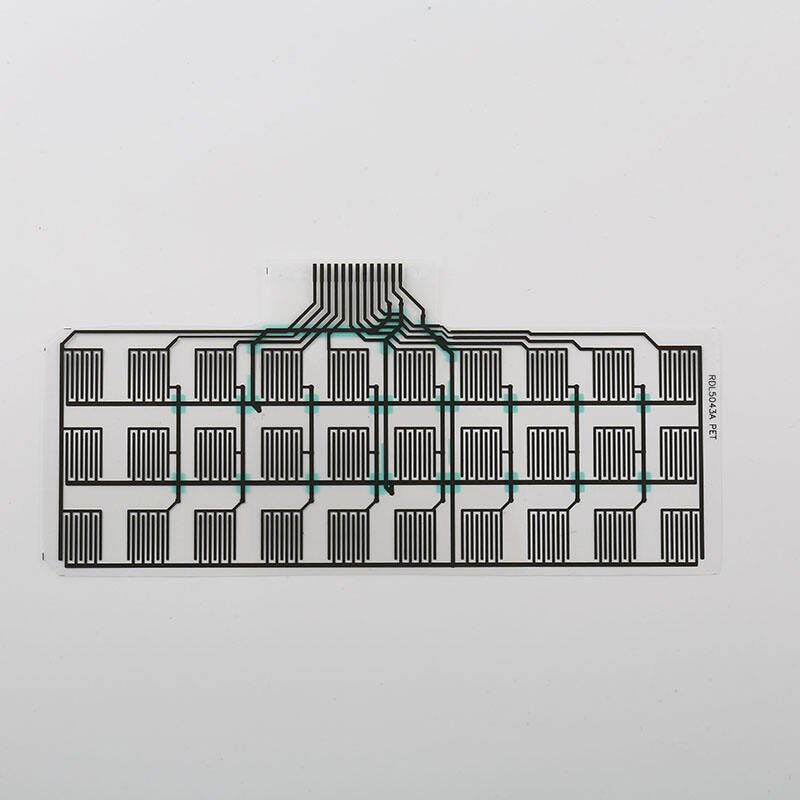

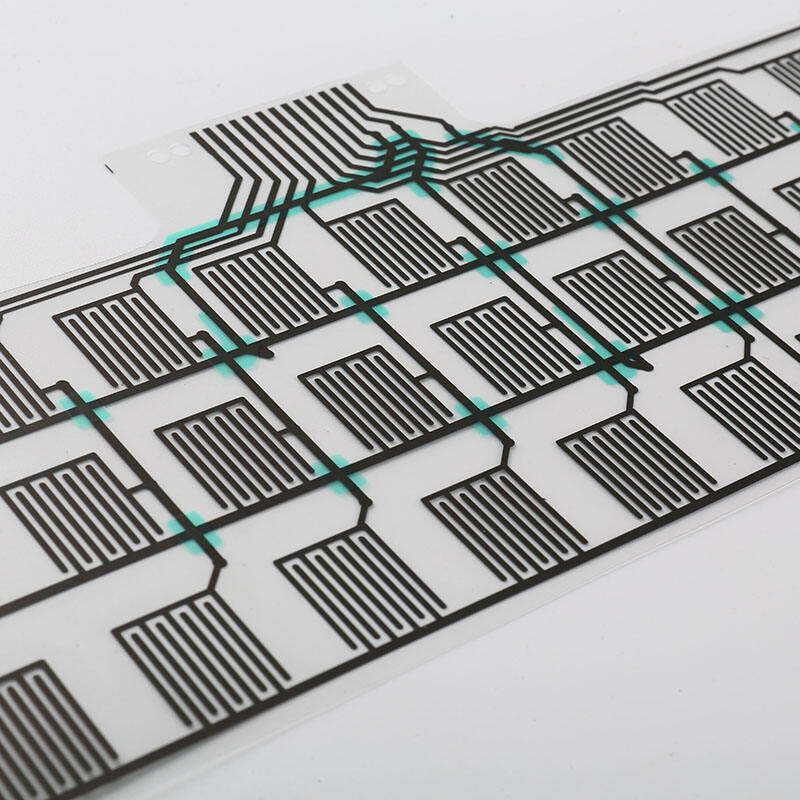

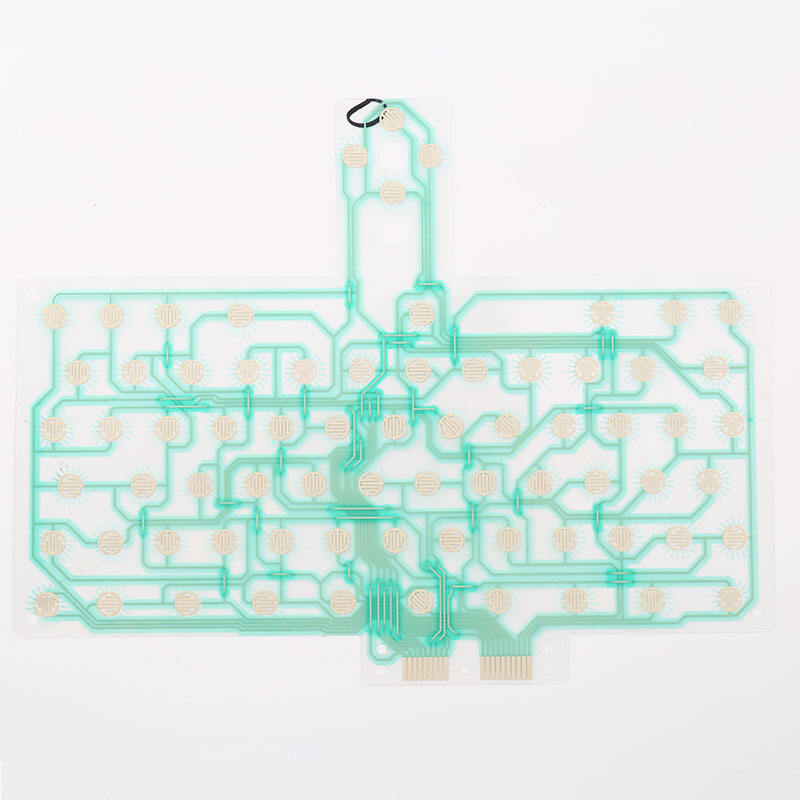

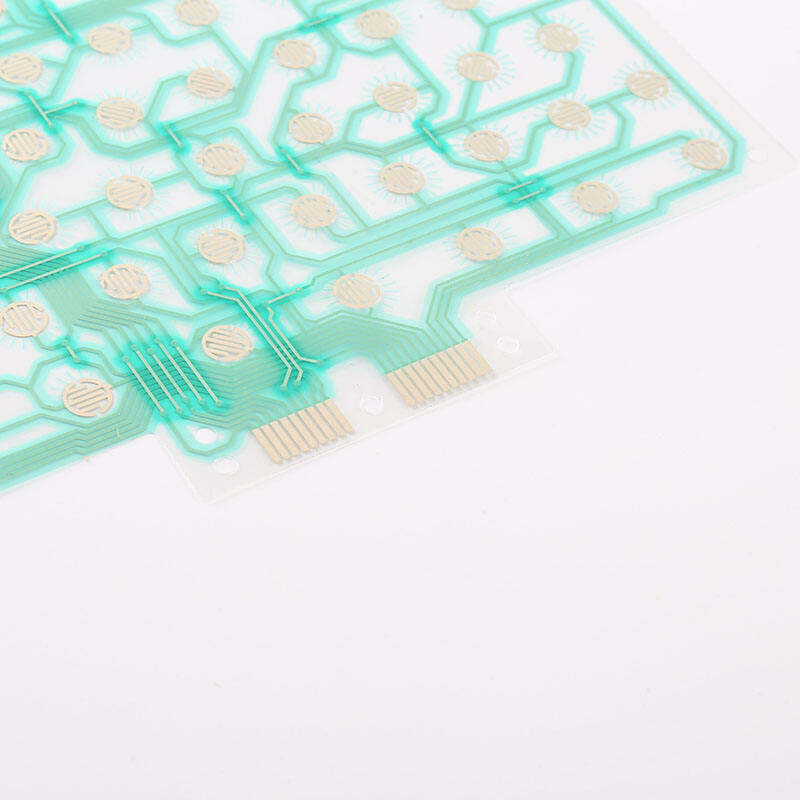

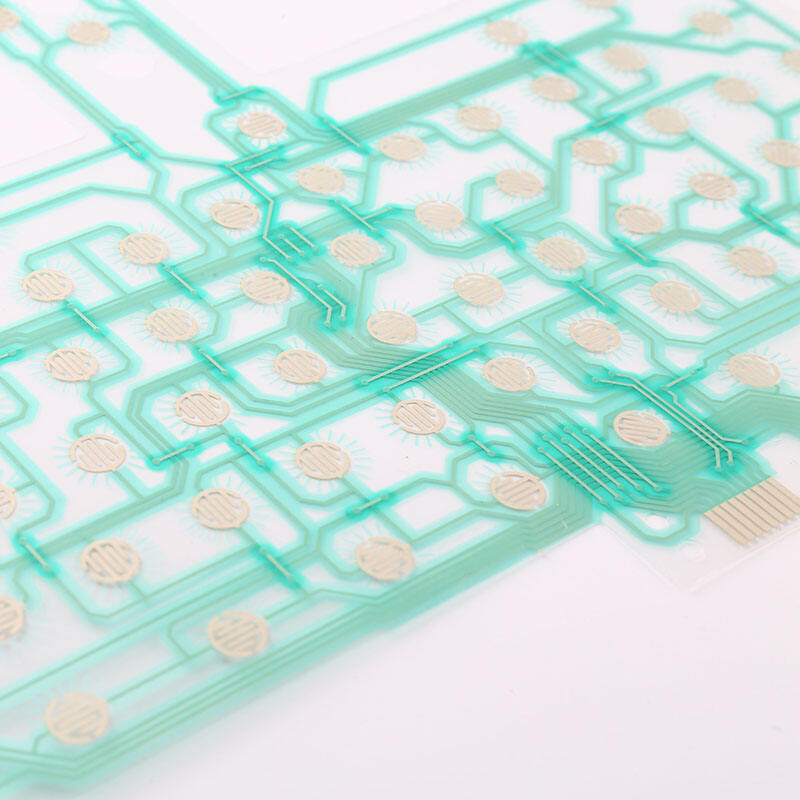

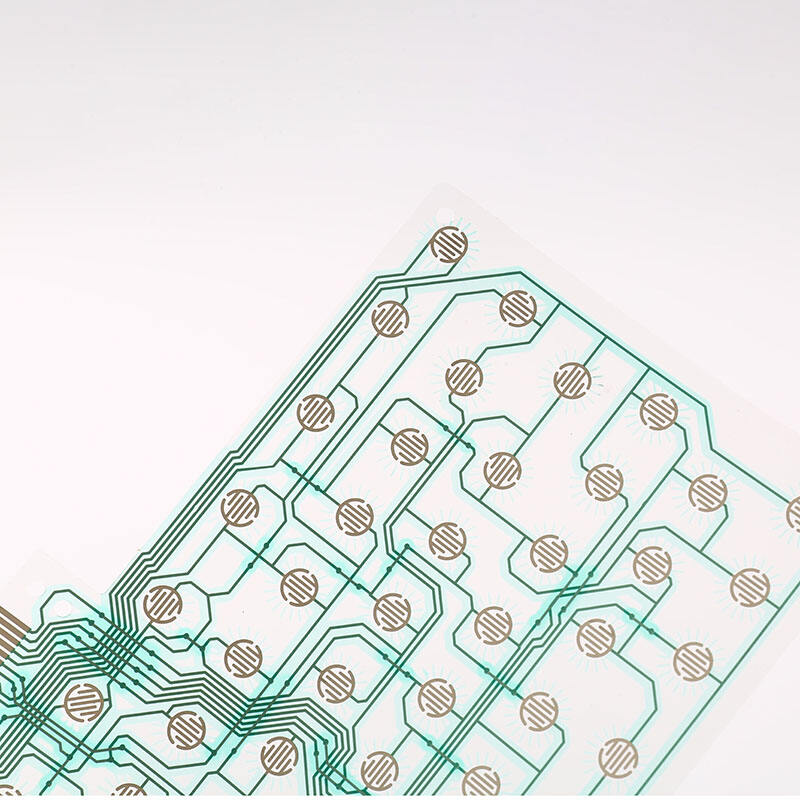

Soft Circuit Membrane Switch

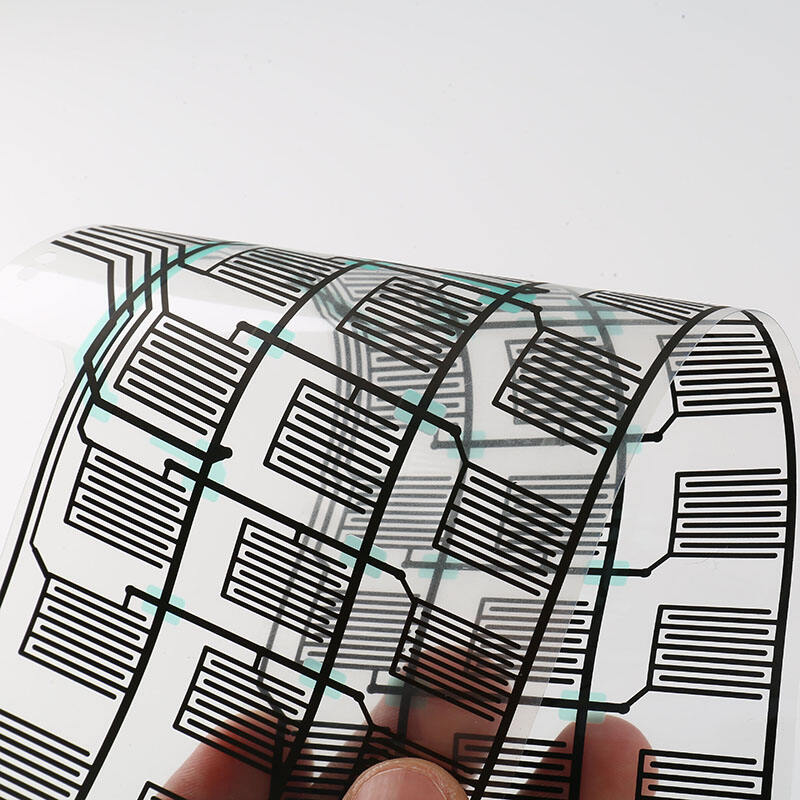

Soft circuits can be developed using polyester or polyimide as the base material, depending on your interface requirements. From simple single layer copper flex on polyester to complex double-sided on polyimide, rapidly provides customers with application-specific solutions.

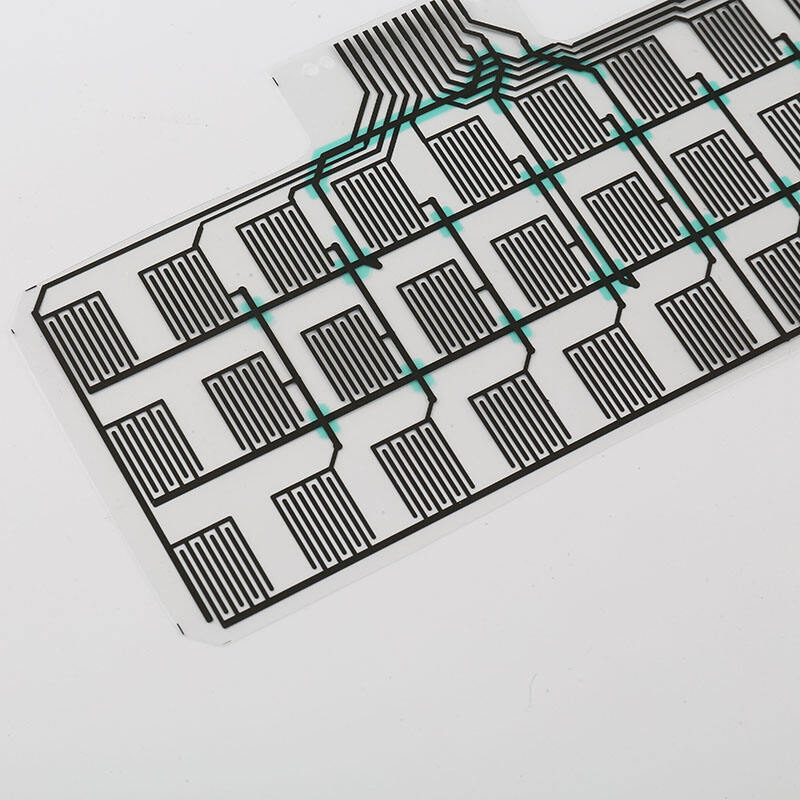

Trace Width

Standard line width-0.25mm, minimum 0.10mm

Standard trace pitch-0.50mm, minimum 0.20mm

Minimum space between-circuits 0.10mm

Plating

Tin-lead, nickel, gold

Component Assembly

Connector crimping

Soldering of components

Base Material

Polyimide: standard thickness-1mil 2mil and 1/2 mil available

Polyester: standard thickness-3mil 1mil, 2mil and 5mil available

Conductor: laminated ED copper or RA copper-standard thickness 1 oz (1.4mil/0.035mm) 1/2 oz and 2 oz available

Coverlay: polyimide, polyester or solder mask thickness-1/2 mil, 1mil, 2mil, 3mil or 5mi

Product Selling Points:

1. Wear-resistant, waterproof, dust-proof, anti-harmful gas, long life, stable performance, small size, light, simple to use

2. Convenient assembly, key life ≥ 1 million times, keys can be embossed with good feel, stable voltage and current, can be equipped with LED lights, resistors and capacitors, etc., can add LGF, EL backlight

3. Various specifications, PC, PET, FPC, acrylic PVC multiple combinations

4. Clear silk screen printing, controllable color, beautiful handwriting, beautiful surface (frosted, smooth, gradient, matte, UV protection), fine, safe and stable circuit, no error, difficult to oxidize.

Enterprise Advantages:

1. Advanced manufacturing process: With high-precision screen printing technology, we can produce membrane switches with clear lines and exquisite patterns. In the hot pressing process, we can accurately control the temperature, pressure and time to ensure the size and quality of the product.

2. Strong R&D capabilities: We have a professional R&D team that can continuously develop new membrane switches.

3. Strict quality inspection system: Through a variety of quality inspection methods, such as testing conductivity, insulation, wear resistance, and pressure resistance tests, we ensure that each membrane switch meets high quality standards.

Product Advantages:

1. Customized service: The shape, size, function (such as special button layout, multiple function combinations) and appearance (including color, pattern) of membrane switches can be customized according to the special needs of customers

2. Product diversity: Provide a rich product line, covering membrane switches of different materials (such as PET, PC film), different thicknesses, and different touches (soft touch, hard touch), to meet the needs of multiple fields such as electronics, medical, and industry.

3. High cost performance: Under the premise of ensuring product quality, by optimizing the production process and reducing the cost of raw materials, the product price is competitive, providing customers with cost-effective membrane switches.

Service Advantages:

1. Quick response to customer needs: We have a professional customer service team that can respond quickly and provide solutions after customers inquire or raise questions, and can provide detailed technical support within 24 hours.

2. Good after-sales service: We provide comprehensive after-sales service, and can quickly handle product quality issues to reduce customer losses.

3. Efficient supply chain management: Ensure a stable supply of raw materials, shorten the production cycle, and deliver products on time.

Technical Advantages:

1. Manufacturing process advantages

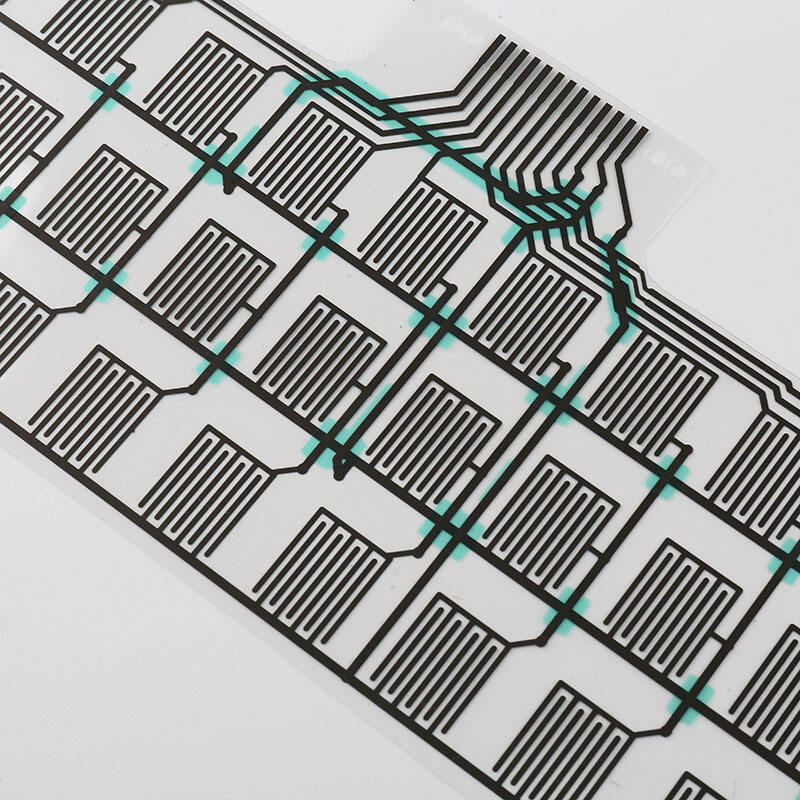

High-precision screen printing: The screen printing process is mature and can achieve high-precision pattern and line printing. Very fine text, icons and circuits can be printed, and the minimum line width can reach tens of microns, ensuring the beautiful appearance and reliable function of the membrane switch.

Precision hot pressing: Hot pressing technology can accurately control parameters such as temperature, pressure and time. This allows different layers of film materials to fit tightly together to form a whole, ensuring the sealing and mechanical properties of the product, while also effectively avoiding problems such as interlayer separation or bubbles.

Automated production process: The introduction of automated production lines, from material cutting, printing, lamination to final inspection, most of the links are automated. This not only improves production efficiency, but also reduces the errors caused by manual operation and ensures the consistency of product quality.

2. Performance advantages

High sensitivity and reliability: The membrane switch has a sensitive touch, short key stroke, uniform trigger force, and can respond quickly to operating instructions. Its internal circuit design is reasonable, the contact is reliable, and it has good anti-interference ability. It can also work stably in complex electromagnetic environments to ensure the accuracy of signal transmission.

Strong durability: It has excellent wear resistance and scratch resistance. After special surface treatment, it can withstand tens of thousands or even more key operations. At the same time, it also has good temperature resistance, can work normally in a wide temperature range, and adapt to different use environments.

Good waterproof and dustproof performance: Through reasonable structural design and the use of sealing materials, membrane switches can effectively prevent the intrusion of dust and liquids. This feature makes it widely used in outdoor equipment, medical equipment, industrial control equipment and other fields with high environmental protection requirements.

Product Selling Points:

1. Wear-resistant, waterproof, dust-proof, anti-harmful gas, long life, stable performance, small size, light, simple to use

2. Convenient assembly, key life ≥ 1 million times, keys can be embossed with good feel, stable voltage and current, can be equipped with LED lights, resistors and capacitors, etc., can add LGF, EL backlight

3. Various specifications, PC, PET, FPC, acrylic PVC multiple combinations

4. Clear silk screen printing, controllable color, beautiful handwriting, beautiful surface (frosted, smooth, gradient, matte, UV protection), fine, safe and stable circuit, no error, difficult to oxidize.

Enterprise Advantages:

1. Advanced manufacturing process: With high-precision screen printing technology, we can produce membrane switches with clear lines and exquisite patterns. In the hot pressing process, we can accurately control the temperature, pressure and time to ensure the size and quality of the product.

2. Strong R&D capabilities: We have a professional R&D team that can continuously develop new membrane switches.

3. Strict quality inspection system: Through a variety of quality inspection methods, such as testing conductivity, insulation, wear resistance, and pressure resistance tests, we ensure that each membrane switch meets high quality standards.

Product Advantages:

1. Customized service: The shape, size, function (such as special button layout, multiple function combinations) and appearance (including color, pattern) of membrane switches can be customized according to the special needs of customers

2. Product diversity: Provide a rich product line, covering membrane switches of different materials (such as PET, PC film), different thicknesses, and different touches (soft touch, hard touch), to meet the needs of multiple fields such as electronics, medical, and industry.

3. High cost performance: Under the premise of ensuring product quality, by optimizing the production process and reducing the cost of raw materials, the product price is competitive, providing customers with cost-effective membrane switches.

Service Advantages:

1. Quick response to customer needs: We have a professional customer service team that can respond quickly and provide solutions after customers inquire or raise questions, and can provide detailed technical support within 24 hours.

2. Good after-sales service: We provide comprehensive after-sales service, and can quickly handle product quality issues to reduce customer losses.

3. Efficient supply chain management: Ensure a stable supply of raw materials, shorten the production cycle, and deliver products on time.

Technical Advantages:

1. Manufacturing process advantages

High-precision screen printing: The screen printing process is mature and can achieve high-precision pattern and line printing. Very fine text, icons and circuits can be printed, and the minimum line width can reach tens of microns, ensuring the beautiful appearance and reliable function of the membrane switch.

Precision hot pressing: Hot pressing technology can accurately control parameters such as temperature, pressure and time. This allows different layers of film materials to fit tightly together to form a whole, ensuring the sealing and mechanical properties of the product, while also effectively avoiding problems such as interlayer separation or bubbles.

Automated production process: The introduction of automated production lines, from material cutting, printing, lamination to final inspection, most of the links are automated. This not only improves production efficiency, but also reduces the errors caused by manual operation and ensures the consistency of product quality.

2. Performance advantages

High sensitivity and reliability: The membrane switch has a sensitive touch, short key stroke, uniform trigger force, and can respond quickly to operating instructions. Its internal circuit design is reasonable, the contact is reliable, and it has good anti-interference ability. It can also work stably in complex electromagnetic environments to ensure the accuracy of signal transmission.

Strong durability: It has excellent wear resistance and scratch resistance. After special surface treatment, it can withstand tens of thousands or even more key operations. At the same time, it also has good temperature resistance, can work normally in a wide temperature range, and adapt to different use environments.

Good waterproof and dustproof performance: Through reasonable structural design and the use of sealing materials, membrane switches can effectively prevent the intrusion of dust and liquids. This feature makes it widely used in outdoor equipment, medical equipment, industrial control equipment and other fields with high environmental protection requirements.