Die Bedeutung von Klebstoffen für die Haltbarkeit von Membranschaltern

Einführung in Klebstoffe und ihre Bedeutung für die Haltbarkeit von Membranschaltern

Klebstoffe sind entscheidende Bestandteile in der Fertigung und bieten eine wesentliche Bindung zwischen Oberflächen. Diese Stoffe sind so konzipiert, dass sie Materialien zusammenhalten, befestigen oder binden, was sich erheblich auf die Haltbarkeit und Leistung des Produkts auswirkt. Durch ihre Haftung und Zusammenhalt bieten Klebstoffe ein wirksames Mittel zur Bindungsbildung, was sie für verschiedene industrielle Anwendungen von unschätzbarem Wert macht.

Im Zusammenhang mit Membranschaltern spielen Klebstoffe eine zentrale Rolle bei Haltbarkeit und Langlebigkeit. Diese Schalter, die für die Benutzeroberflächentechnologie von entscheidender Bedeutung sind, sind für ihre strukturelle Integrität und Zuverlässigkeit auf Klebstoffe angewiesen. Ein gut ausgewählter Klebstoff kann die Verschleißfestigkeit des Schalters und die Umweltfaktoren erhöhen und so eine gleichbleibende Leistung im Laufe der Zeit gewährleisten.

Die Bedeutung von Klebstoffen in der Fertigung wird durch ihre Verbreitung in allen Branchen unterstrichen. So wird beispielsweise der globale Markt für Klebstoffe bis 2025 voraussichtlich 50 Milliarden Dollar erreichen, was ihre unverzichtbare Rolle unterstreicht. Dieses Wachstum spiegelt Fortschritte in der Klebertechnologie wider, die durch die steigende Nachfrage nach innovativen Kleberlösungen in verschiedenen Anwendungen angetrieben werden.

Arten von Klebstoffen, die bei der Herstellung von Membranschaltern verwendet werden

Druckempfindliche Klebstoffe (PSA) sind in der Membranschalterherstellung von entscheidender Bedeutung, da sie für ihre einfache Verwendung und ihre sofortige Bindung bekannt sind. Diese Klebstoffe erfordern nur geringen Druck, um eine Bindung zu bilden, wodurch Hitze oder Lösungsmittel nicht benötigt werden, was sie ideal für Anwendungen macht, die eine schnelle und effiziente Bindung erfordern. PSAs sind in verschiedenen Branchen, wie beispielsweise in der Automobilindustrie und in der Unterhaltungselektronik, sehr vielseitig, da sie für Komponenten wie Armaturenbretter und elektronische Displays verwendet werden.

PSAs werden besonders wegen ihrer Anpassungsfähigkeit an verschiedene Oberflächen, einschließlich Metalle, Kunststoffe und Glas, geschätzt. Diese Eigenschaft ist für Industriezweige von entscheidender Bedeutung, die eine schnelle und vorübergehende Adhäsion ohne Rückstandsgefahr bei der Entfernung verlangen. Im Automobilbereich werden PSAs zum Anschließen von Ausstattungsteilen und Innenplatten verwendet, während sie in der Unterhaltungselektronik Komponenten wie Bildschirme und Tasten sichern und so die ästhetische und funktionale Integrität des Geräts verbessern.

Epoxy- und Polyurethanklebstoffe spielen eine wichtige Rolle bei der Verbesserung der strukturellen Integrität von Membranschaltern, da sie eine erhebliche Festigkeit und Beständigkeit gegen raue Umweltbedingungen bieten. Epoxydähte sind bekannt für ihre Langlebigkeit und chemische Beständigkeit, was sie für Anwendungen geeignet macht, bei denen Zuverlässigkeit und Langlebigkeit von größter Bedeutung sind. Im Gegensatz dazu bieten Polyurethanklebstoffe eine hervorragende Flexibilität und Widerstandsfähigkeit gegen Aufprall und Feuchtigkeit, was für Anwendungen, bei denen ein gewisses Maß an Materialbewegung erforderlich ist, entscheidend ist.

Die Wahl zwischen Epoxidhänge und Polyurethanklebstoffen hängt häufig von den spezifischen Anforderungen an das Produkt ab. In Szenarien, in denen beispielsweise hohe Tragfähigkeit und chemische Beständigkeit erforderlich sind, würde Epoxid bevorzugt werden, wie in der Luft- und Raumfahrtindustrie und der Automobilindustrie. Umgekehrt eignet sich Polyurethan für Situationen, in denen Vibrationsdämpfung und Flexibilität erforderlich sind, wie in der Unterhaltungselektronik oder im Bauwesen. Diese strategische Auswahl auf der Grundlage von Klebstoff-Eigenschaften gewährleistet optimale Leistung und Langlebigkeit bei Membranschalteranwendungen.

Wie Klebstoffe die Haltbarkeit von Membranschaltern beeinflussen

Die Haltbarkeit von Klebstoffen in Membranschaltern wird weitgehend durch Kohäsions- und Klebkraft beeinflusst, die für ihre Leistung von entscheidender Bedeutung sind. Kohäsionskräfte sind die innere Stärke, die die Moleküle des Klebstoffs zusammenhält, während Klebkraft beschreibt, wie gut die Klebstoffbindungen mit den Oberflächen, auf die es aufgetragen wird, zusammenhalten. Wenn diese Kräfte ausgeglichen sind, sorgen sie für eine starke, zuverlässige Verbindung, die die Haltbarkeit des Schalters erhöht. Wenn z. B. Kohäsionskräfte die Klebkraft übersteigen, kann ein Klebstoffversagen auftreten, wodurch der Klebstoff in sich zerfällt und die Bindung beeinträchtigt wird.

Ein Klebstoffversagen bei Membranschaltern kann aus verschiedenen Gründen entstehen, einschließlich einer unzureichenden Oberflächenvorbereitung, einer schlechten Klebstoffwahl und einer Exposition gegenüber Umweltfaktoren. Häufige Folgen eines Klebstoffversagens sind eine verringerte Lebensdauer und Funktionalität des Schalters, wie verschiedene Fallstudien in der Industrie belegen. Ein Industriebericht ergab beispielsweise, dass eine unsachgemäße Aufkleberwahl zu einem Anstieg der Produkterträge um 20% durch vorzeitiges Ausfall von Anleihen führte. Solche Fehler unterstreichen die Notwendigkeit, die geeigneten Klebstoffe für bestimmte Anwendungen gründlich zu verstehen und auszuwählen.

Umweltbedingungen wie Temperatur und Feuchtigkeit beeinflussen die Klebstoffleistung erheblich und beeinflussen die Lebensdauer von Membranschaltern. Hohe Temperaturen beispielsweise können zu einer Erweißung des Klebstoffs führen, während Feuchtigkeit zu Schwellungen und einem Verlust der Haftung führen kann. Untersuchungen zeigen, daß Klebstoffe bei ständiger Exposition gegenüber hohen Temperaturen und Feuchtigkeit bis zu 50% ihrer Festigkeit verlieren können. Dies unterstreicht die Bedeutung der Auswahl von Klebstoffen, die spezifischen Umweltbedingungen standhalten sollen, um die Integrität und Haltbarkeit von Membranschaltern im Laufe der Zeit zu erhalten.

Wichtige Faktoren bei der Wahl von Klebstoffen für Membranschalter

Die Wahl des richtigen Klebstoffs für Membranschalter ist entscheidend, um die Materialkompatibilität zu gewährleisten. Unvereinbare Klebstoffe können zu Delamination oder einer beeinträchtigten Funktionalität führen. Um die Kompatibilität effektiv zu testen, können Methoden wie Peel-Tests, Scherentests und Umweltsimulationen verwendet werden. Diese Tests helfen, die Leistung des Klebstoffs unter verschiedenen Belastungsbedingungen zu beurteilen und sicherzustellen, dass es eine dauerhafte Bindung mit dem Membranmaterial bildet.

Verschiedene Materialien, die in Membranschaltern verwendet werden, erfordern spezifische Klebstoffe für eine optimale Leistung. So passen Polyestermembranen oft gut zu Acrylklebstoffen zusammen, was zu einer starken Bindung und Flexibilität führt. Polycarbonatmembranen können aufgrund ihrer Fähigkeit, thermische Ausdehnung und Kontraktion zu bewältigen, von Polyurethanklebstoffen profitieren. Die Verständnis dieser Paarungen ist für die Auswahl geeigneter Klebstoffe für jeden Membrantyp unerlässlich.

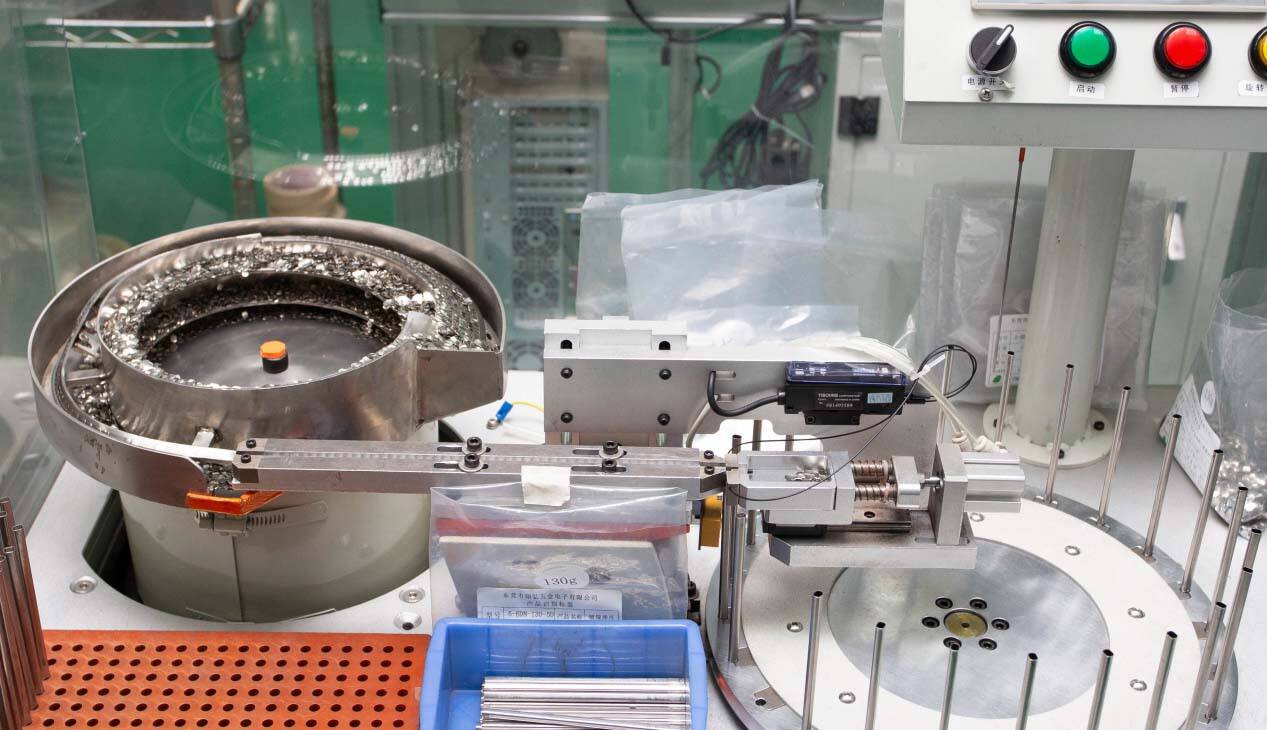

Anwendungsverfahren wie Oberflächenvorbereitung und Härteverfahren haben erhebliche Auswirkungen auf die Wirksamkeit von Klebstoffen. Eine ordnungsgemäße Oberflächenvorbereitung sorgt für eine maximale Bindungsfestigkeit, indem Verunreinigungen, die die Haftung behindern können, entfernt werden. Auch die Verhärtung spielt eine wichtige Rolle, denn sie ermöglicht es dem Klebstoff, seine volle Festigkeit und Langlebigkeit zu erreichen. Techniken wie die Anwendung von Härte oder die Verwendung von UV-Härtungssystemen können diesen Prozess beschleunigen.

Befolgen Sie die Anweisungen des Herstellers für die Anwendung von Klebstoffen, um optimale Ergebnisse zu erzielen. Die Verwendung der empfohlenen Temperaturen, Feuchtigkeitsniveaus und Anwendungsmethoden stellt sicher, dass der Klebstoff wie erwartet wirkt. Diese Leitlinien, die durch umfangreiche Tests und Analysen erstellt wurden, sollen spezifische Haftungen an den Membranschaltermaterialien beheben und so die Lebensdauer und Funktionalität des Produkts maximieren. Sie sollten sich immer an diese Anweisungen halten, um häufige Probleme bei der Anwendung von Klebstoffen zu vermeiden.

Vorzugene Produkte: Klebstoffe für Membranschalter

Die Wahl des richtigen Klebstoffs ist für Membranschalter von entscheidender Bedeutung, um Zuverlässigkeit und Leistung zu gewährleisten.

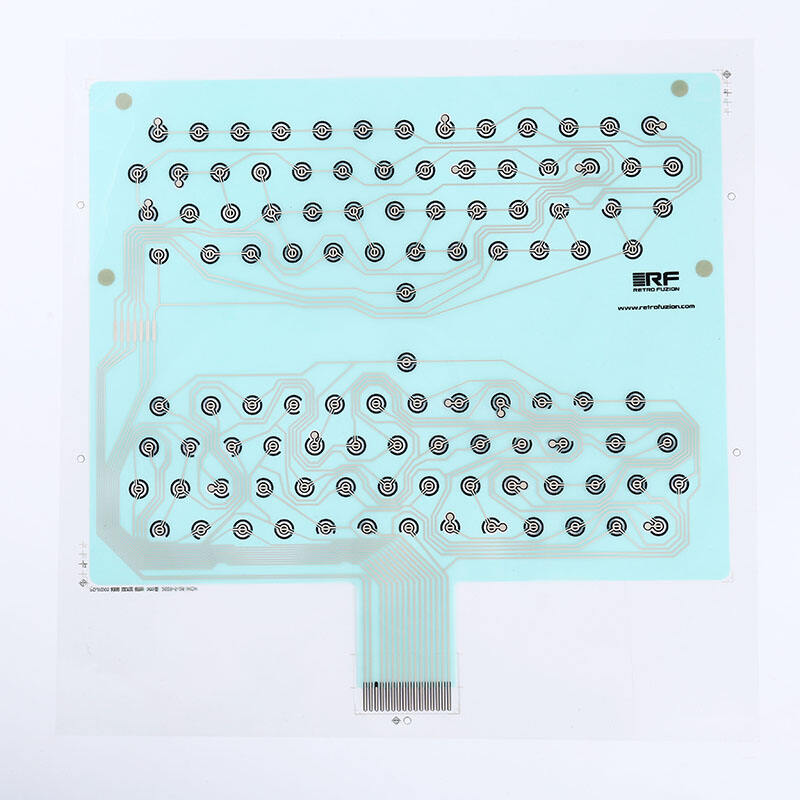

Benutzerdefinierte Backit-Membran-Schalter

Die Benutzerdefinierte Backit-Membran-Schalter sie zeichnet sich durch ihre hervorragende Kompatibilität mit einer Vielzahl von Klebstoffen aus und bietet eine hervorragende Haltbarkeit und Haftbarkeit unter verschiedenen Umweltbedingungen. Dieses Produkt bietet vielseitige Anwendungsmöglichkeiten und ist somit eine bevorzugte Wahl für kundenspezifische Lösungen.

Fernbedienung Membran-Schalter-Panel

Die Fernbedienung Membran-Schalter-Panel spezifische Anforderungen an Klebstoffe hat, die bei der Verwendung in Fernanwendungen eine optimale Funktionalität und Langlebigkeit gewährleisten. Die Konstruktion ermöglicht eine effektive Bindung mit verschiedenen Klebstofftypen und erhöht so die Effizienz und Zuverlässigkeit des Schalters.

Membranschaltkreisschalter

Für die Membranschaltkreisschalter , ist die Wahl des richtigen Klebstoffs entscheidend, um seine elektrische Leistungsfähigkeit und Haltbarkeit zu verbessern. Die spezifischen Klebstoffe, die in diesem Produkt verwendet werden, machen den Schaltkreislauf robust und außergewöhnlich zuverlässig und erfüllen strenge Industriestandards.

Led-Membran-Schalter

Schließlich der Led-Membran-Schalter erfordert Klebstoffe, die eine hohe Haltbarkeit und eine außergewöhnliche Leistungsfähigkeit bieten. Diese Klebstoffe müssen unterschiedlichen Betriebsumgebungen standhalten und gleichzeitig die visuellen und funktionalen Anforderungen des Schalters erfüllen.

Hot News

-

Anweisungen für die Probenahme der Membranschalterplatte

2023-12-14

-

Kennst du die Gründe, warum heiße Scheiben nicht aufspringen, wenn sie gepresst werden?

2023-12-14

-

Was ist ein Lichtführer? Hongmao ist spezialisiert auf die Herstellung von Lichtführerblättern, wussten Sie das?

2023-12-14

-

Wie viele Regler sind nötig, um einen Membranwechsel zu machen?

2023-12-14

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI