Vergleich verschiedener Filmtypen für Membranschalter

Verständnis von Membranschaltern

Die Membranschaltertechnologie spielt eine entscheidende Rolle in Benutzeroberflächen verschiedener elektronischer Geräte und bietet eine Mischung aus Langlebigkeit, Flexibilität und Kosteneffizienz. Die Membranschalter, die in den 1980er Jahren entstanden sind, haben sich erheblich weiterentwickelt und sind aufgrund ihrer zuverlässigen Leistung und Anpassungsfähigkeit zu einer beliebten Wahl für Designer geworden. Diese Schalter werden typischerweise in Branchen eingesetzt, die von medizinischen Geräten über Unterhaltungselektronik bis hin zu Industriemaschinen reichen, wo die Interaktion mit dem Benutzer und die Schaltkreissteuerung für die Funktionalität des Geräts unerlässlich sind. Ein Membranschalter besteht aus mehreren Schlüsselkomponenten, die harmonisch zusammenarbeiten, um einen nahtlosen Betrieb zu gewährleisten. Dazu gehören: 1. Graphische Überlagerung : Die oberste Schicht, oft aus Polyester oder Polycarbonat, zeigt Symbole und grafische Designs für die Interaktion mit dem Benutzer. 2. Die Klebeabstand : Diese Schicht hält den Abstand zwischen der grafischen Überlagerung und der Schaltung, um zufälligen Kontakt zu verhindern und sorgt dafür, dass die Taste in ihre ursprüngliche Position zurückkehrt. 3. Die Schaltkreisschicht : Diese Schicht, die als Herz des Membranschalters bekannt ist, enthält leitfähige Spuren, die typischerweise mit Silber oder Kupfer bedruckt sind, um den elektrischen Stromkreis zu bilden. 4. Die Schutzschichten : Diese erhöhen die Haltbarkeit und die Umweltschutzfähigkeit und schützen den Schalter vor Schäden durch Feuchtigkeit und Schadstoffe. Die Funktionsmechanik von Membranschaltern dreht sich um eine einfache, aber wirksame Drückfunktion. Wenn ein Benutzer die grafische Überlagerung drückt, wird die oberste Schaltungsschicht mit der unteren Schaltungsschicht in Berührung gebracht und ein kompletter elektrischer Schaltkreis hergestellt. Diese Aktion wird als Kontaktschließung bezeichnet und sendet ein Signal an das angeschlossene Gerät, das die Ausführung der Funktion ermöglicht. Sobald der Druck entfesselt ist, bricht der Stromkreis, kehrt in seinen offenen Zustand zurück und das Gerät wartet auf weitere Eingaben. Das Verständnis dieser Komponenten und Mechaniken verdeutlicht, warum Membranschalter in modernen Geräteoberflächen vielseitig und von unschätzbarem Wert sind.Arten von Membranschaltern

Membranschalter gibt es in verschiedenen Typen, die jeweils für bestimmte Anwendungen geeignet sind. Schalter mit taktiler Membran sie bieten physikalisches Feedback und eignen sich daher ideal für Umgebungen, in denen der Benutzer die Eingabe bestätigen muss, wie z. B. industrielle Steuerungen. Sie verwenden Metall- oder Polydomstrukturen, um einen spürbaren "Snap" oder Klickgeräusch zu erzeugen, was die Interaktion mit dem Benutzer verbessert. Im Gegensatz dazu mit einem Stromgehalt von mehr als 50 W diese Rückmeldung fehlt, so dass eine glatte und flache Schnittstelle geboten wird. Diese werden häufig in Anwendungen verwendet, in denen der Raum begrenzt ist oder Kosteneffizienz bevorzugt wird, wie beispielsweise Fernbedienungen. Rücklichter-Membranschalter für Umgebungen mit schlechten Lichtverhältnissen ausgelegt sind. Sie sind mit Lichtquellen wie LEDs ausgestattet, die auch im Dunkeln Sichtbarkeit gewährleisten und somit für den nächtlichen Betrieb von Fahrzeugen oder Industrieanlagen geeignet sind. Außerdem mit einem Stromgehalt von mehr als 10 W sind für Produkte, die rauen Umweltbedingungen ausgesetzt sind, einschließlich Außengeräten, unerlässlich. Sie sind mit Schutzbarrieren ausgestattet, um Wasserdurchdringung zu verhindern und somit ihre Haltbarkeit und Zuverlässigkeit zu verbessern. Schließlich ist es wichtig, den Unterschied zwischen mit einem Stromgehalt von mehr als 50 W und ist entscheidend. Kapazitive Schalter reagieren auf Berührungen ohne Druck von außen; sie sind häufig in modernen Smartphones und Touchpads zu finden. Umgekehrt erfordern resistente Schalter einen physikalischen Druck, um zu funktionieren, oft in industriellen Anwendungen wie berührungsbasierten Betriebssystemen, wo die Umgebung weniger förderlich für kapazitive Bildschirme ist. Jeder Schalter hat seine eigenen Vorteile und kann entsprechend den spezifischen Bedürfnissen der Nutzer und den Umweltanforderungen angepasst werden.Anwendungen von Membranschaltern

Membranschalter werden aufgrund ihrer Flexibilität, Haltbarkeit und Kosteneffizienz in wichtigen Branchen wie Gesundheitswesen, Automobilindustrie und Unterhaltungselektronik weit verbreitet. Im Gesundheitswesen werden Membranschalter wegen ihrer einfachen Reinigung und ihrer Fähigkeit, harten Desinfektionsmitteln standzuhalten, bevorzugt, was sie ideal für medizinische Instrumente und Laborgeräte macht. Die Automobilindustrie profitiert von ihrem schlanken Aussehen und ihrer zuverlässigen Leistung unter verschiedenen Umweltbedingungen, insbesondere bei Armaturenbrettsteuerungen und Fernbedienungen für Fahrzeuge. In der Unterhaltungselektronik verbessern die Integrationsflexibilität und das anpassbare Design von Membranschaltern die Benutzerinteraktion und die Ästhetik des Geräts. In der Unterhaltungselektronik bieten Membranschalter nahtlose Benutzeroberflächen, die die Benutzererfahrung erheblich verbessern. Geräte wie Smartphones und Spielekonsolen integrieren diese Schalter, um schlanke, reaktionsschnelle Steuerungen ohne umständliche mechanische Tasten zu ermöglichen. Außerdem profitieren Haushaltsgeräte von den ästhetischen und funktionalen Vorteilen von Membranschaltern, da sie intuitive Bedienelemente bieten, die sich gut an jede Umgebung anpassen. Die Anwendung von Membranschaltern erstreckt sich auf industrielle Steuerungssysteme und medizinische Geräte, bei denen ihre Zuverlässigkeit von größter Bedeutung ist. In Industriebetrieben halten diese Schalter harten Umgebungsbedingungen stand und sorgen für einen zuverlässigen Betrieb von Maschinen und Geräten. Medizinische Geräte nutzen Membranschalter für ihre Präzision und Benutzerfreundlichkeit und tragen so zu sichereren und effizienteren Gesundheitsoperationen bei. In beiden Bereichen sind Membranschalter aufgrund ihrer einfachen Bedienung und ihrer Beständigkeit gegenüber Umweltfaktoren für anspruchsvolle Umgebungen unverzichtbar.Wichtige Vorteile von Membranschaltern

Membranschalter zeichnen sich durch ihre Langlebigkeit und Wirtschaftlichkeit gegenüber traditionellen Schaltertechnologien aus, was sie in verschiedenen Branchen zu einer bevorzugten Wahl macht. Sie sind ohne bewegliche Teile ausgelegt, was zu einem geringeren Verschleiß führt und zu einer erheblichen Langlebigkeit beiträgt. Studien zeigen, daß Membranschalter über eine Million Operationen durchhalten können, was ihre Langlebigkeit unterstreicht. Darüber hinaus wird ihre Kosteneffizienz durch den geringeren Bedarf an häufigen Austausch und Wartung unterstützt, was im Vergleich zu mechanischen Schaltern die Lebenszykluskosten senken kann. Ein weiterer wesentlicher Vorteil von Membranschaltern ist ihre hohe Anpassungsfähigkeit, die unterschiedlichen Marken- und Produktanforderungen gerecht wird. Hersteller können verschiedene grafische Design-Überlagerungen, Materialien und Funktionen anbieten, die sich an die spezifische Ästhetik und den funktionalen Bedürfnissen der Marke anpassen. Optionen wie Hintergrundbeleuchtung, erhöhte Kuppel-Tasten und taktiles oder nicht-taktiles Feedback fügen eine Vielzahl von Personalisierungsmöglichkeiten hinzu, die einzigartige Benutzererlebnisse ermöglichen und den Wert des Produkts erhöhen. Diese Flexibilität ermöglicht es Marken, Membranschalter nahtlos in ihre Produktentwürfe zu integrieren. Die einfache Wartung und Reinigung bietet Membranschaltern einen deutlichen Vorteil, insbesondere in Bereichen, in denen Hygiene von entscheidender Bedeutung ist, wie z. B. bei medizinischen oder industriellen Anwendungen. Experten geben zu, daß die Versiegelung dieser Schalter nicht nur Schmutz und Flüssigkeit verhindert, sondern auch eine einfache Reinigung mit verschiedenen Reinigungsmitteln ermöglicht. Diese Eigenschaft ist entscheidend für die Aufrechterhaltung steriler Umgebungen und stellt so die Einhaltung der Gesundheits- und Sicherheitsstandards in sensiblen Anwendungen sicher.Innovative Produkte in der Membranschalttechnik

Wasserdichte Membranschalter zeichnen sich als entscheidende Innovation in der Membranschalterindustrie aus, insbesondere für Anwendungen, bei denen der Kontakt mit Wasser unvermeidlich ist. Die Nachfrage nach ihnen steigt in Bereichen wie Schiffsausrüstung, Outdoor-Elektronik und Industriegeräten, in denen Feuchtigkeit nicht vermieden werden kann. Die Leistung von wasserdichten Membranschaltern wird durch ihre einzigartigen Eigenschaften verbessert. Diese Schalter sind mit fortschrittlichen Materialzusammensetzungen und außergewöhnlichen Dichtungsverfahren ausgestattet, um eine Wasserdichtigkeit zu gewährleisten. Diese Eigenschaften schützen nicht nur die interne Schaltung, sondern sorgen auch dafür, dass die Funktionalität auch in rauen Umgebungen erhalten bleibt. Wasserdichte Membranschalter sind ein Beispiel für die Fähigkeit der Industrie, spezifische Herausforderungen zu bewältigen, denen Hersteller bei der Entwicklung von langlebigen und zuverlässigen Schnittstellen gegenüberstehen.Zukunftstrends bei der Entwicklung von Membranschaltern

Die Zukunft der Membranschaltertechnologie wird durch neue Trends wie die Integration intelligenter Technologien und Fortschritte bei Touchscreen-Funktionen geprägt. Da digitale Schnittstellen immer häufiger verbreitet werden, steigt die Nachfrage nach Membranschaltern, die intelligente Funktionen wie IoT-Konnektivität und multifunktionale Touchscreen-Schnittstellen enthalten. Diese Fortschritte verbessern nicht nur die Interaktion mit dem Benutzer, sondern erweitern auch den Anwendungsbereich von Membranschaltern in verschiedenen Branchen, einschließlich Automobil, Gesundheitswesen und Unterhaltungselektronik. Außerdem erlebt die Industrie bei der Produktion von Membranschalter einen deutlichen Wandel hin zu nachhaltigen Materialien und umweltfreundlichen Konstruktionen. Die Hersteller setzen umweltfreundliche Produktionstechniken und biologisch abbaubare Materialien an, um der steigenden Nachfrage nach grünen Technologien gerecht zu werden. Branchenexperten gehen davon aus, dass dieser Trend weiter an Dynamik gewinnen wird, da innovative Konzepte und strengere Vorschriften Unternehmen zu nachhaltigeren Praktiken führen werden. Die Einhaltung dieser Trends wird nicht nur zur Erhaltung der Umwelt beitragen, sondern auch Unternehmen als Führungspersönlichkeiten in der innovativen und verantwortungsvollen Fertigung positionieren.Hot News

-

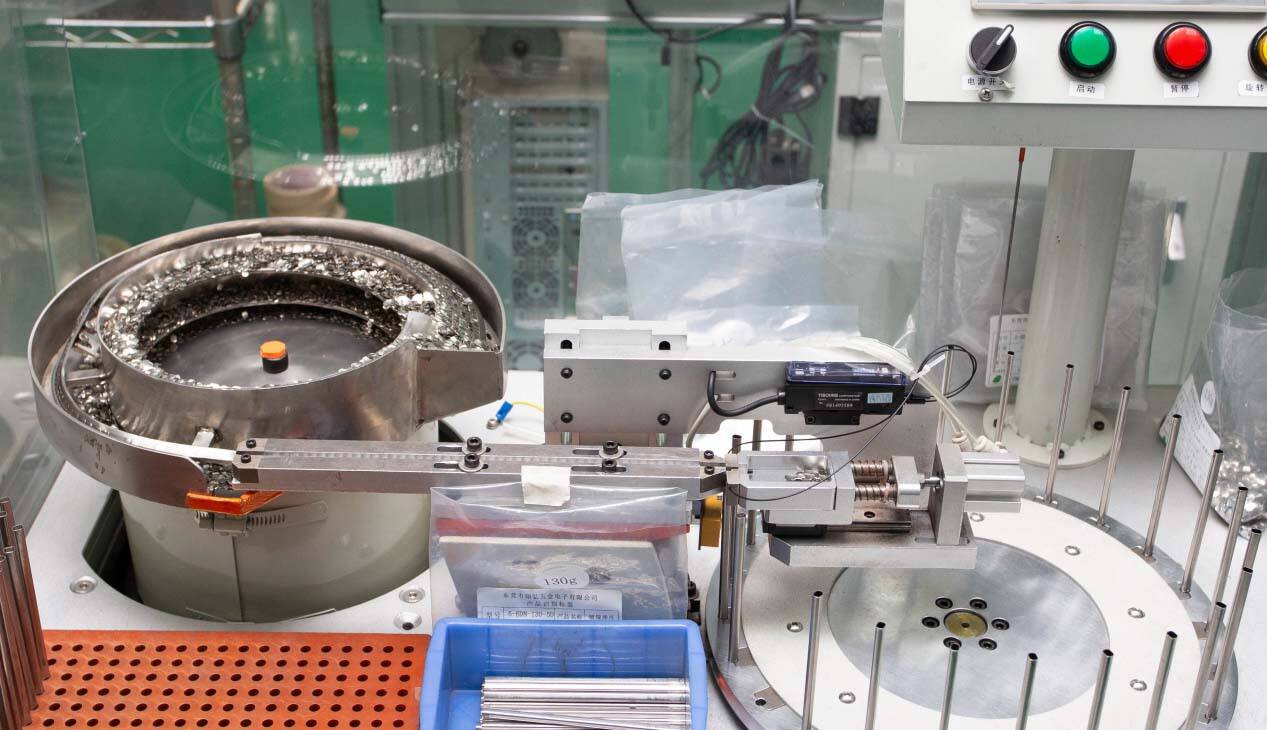

Anweisungen für die Probenahme der Membranschalterplatte

2023-12-14

-

Kennst du die Gründe, warum heiße Scheiben nicht aufspringen, wenn sie gepresst werden?

2023-12-14

-

Was ist ein Lichtführer? Hongmao ist spezialisiert auf die Herstellung von Lichtführerblättern, wussten Sie das?

2023-12-14

-

Wie viele Regler sind nötig, um einen Membranwechsel zu machen?

2023-12-14

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI