We all want a reliable membrane switch, and here's how to get one with great features.

Key Features of Reliable Membrane Switches

Durability and Material Quality

The durability and material quality of membrane switches are essential factors that influence their performance and longevity. Materials with high tensile strength and tear resistance, such as polyester and polycarbonate, are commonly used in membrane switches due to their robustness. Polyester is praised for its excellent durability and chemical resistance, making it a preferred choice for environments with high wear and harsh conditions. Conversely, polycarbonate offers superior clarity and can be thermally formed, offering flexibility in design. However, it tends to be less resistant to abrasive environments. Adhering to test standards like ASTM ensures that membrane switches meet specific durability expectations. For example, the ASTM D1004 standard can evaluate the tear strength of materials, providing a benchmark for durability. Industry statistics indicate that products meeting these rigorous standards exhibit a significantly improved lifespan and reliability.

Tactile vs Non-Tactile Feedback

Tactile feedback in membrane switches significantly enhances user experience by providing physical confirmation during operation. Tactile feedback, achieved through embossed surfaces or dome switches, allows users to feel a "click" sensation, which is often preferred for its reassuring interaction. Surveys have shown that many users appreciate this form of feedback because it minimizes errors and speeds up operation. In contrast, non-tactile switches provide a smoother surface without the clicking sensation, beneficial for applications where speed is crucial, and tactile feedback might slow the process down. Technological advancements have improved tactile response by incorporating refined materials and mechanisms, which have increased user engagement without sacrificing design flexibility, enabling developers to enhance the interaction profile tailored to specific user needs.

Environmental Resistance Standards

Environmental resistance is a critical aspect of membrane switch design, ensuring functionality under various conditions. Standards like IP ratings (Ingress Protection) assess a switch's ability to withstand elements like moisture and dust. A switch with a high IP rating, such as IP67, demonstrates superior resilience under adverse conditions, ensuring reliability by preventing ingress of water and particulates. Research indicates that switches subjected to extreme conditions without these standards tend to fail at a rate significantly higher than those compliant with them. Compliance with industry standards is crucial for the effective performance of membrane switches. Thus, manufacturing practices that align with these standards not only uphold quality but also reassure users of the product's resilience and long-term operational reliability.

Material Selection for Longevity

Polyester vs Polycarbonate Overlays

When it comes to overlays in membrane switches, choosing between polyester and polycarbonate is essential for ensuring longevity and cost-effectiveness. Polyester overlays are renowned for their superior durability, particularly in terms of tensile strength and tear resistance, making them ideal for high-use applications. They are also less susceptible to environmental wear and tear, such as UV exposure and extreme temperatures. Polycarbonate, on the other hand, offers excellent clarity and can be more cost-effective; however, it is generally more prone to scratching and chemical damage. According to market research, polyester is preferred in applications demanding high endurance, while polycarbonate is often chosen for consumer electronics where visual clarity is key. Selecting the right material is crucial and should be aligned with the specific demands of the membrane switch's application. For applications where durability is critical, polyester is typically the better choice.

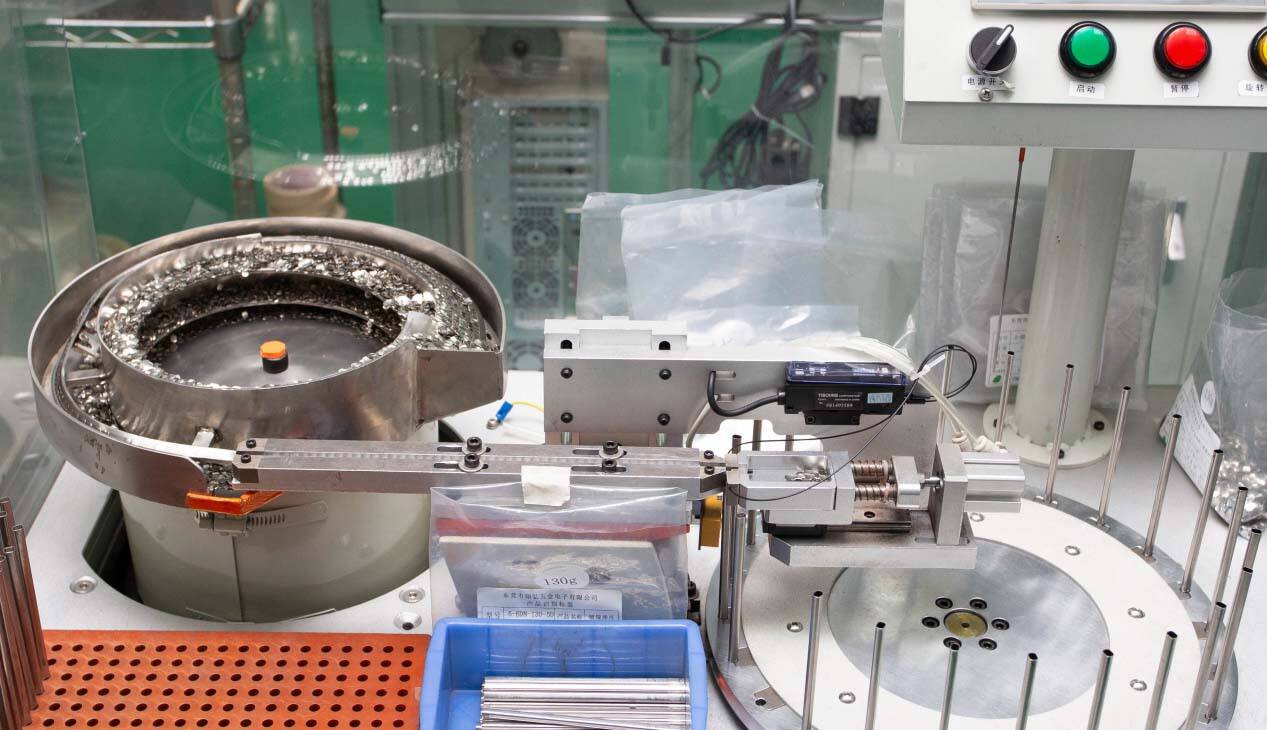

Conductive Inks and Circuit Reliability

Conductive inks play a pivotal role in membrane switches, significantly impacting circuit reliability. These inks create pathways for electrical current within the switch, and their selection can influence overall performance and longevity. There are several types of conductive inks, including carbon, silver, and copper. Carbon inks are economical with moderate conductivity, often used where cost is a primary concern. Silver inks provide high conductivity and are commonly used in applications requiring reliable performance. Copper inks offer a balance between electrical performance and cost but require careful handling to prevent oxidation. Case studies reveal that silver inks have been successfully used in medical equipment, where reliability is non-negotiable, while carbon inks have occasionally led to circuit failures in high-power applications. Selecting the appropriate conductive ink is crucial for ensuring that membrane switches perform reliably in their intended environments.

Design Considerations for Optimal Performance

Customization for User Experience

Customization is pivotal in designing membrane switches to enhance user interaction and satisfaction. A tailored design accommodates diverse user requirements, offering a seamless interface that can significantly elevate the user's experience. Successful custom membrane switch designs can be observed across various industries, such as healthcare, automotive, and electronics. For example, medical devices often use specific button layouts and graphic overlays customized to facilitate ease of use even in critical situations. Design elements such as button placement, tactile feedback, and intuitive interfaces play crucial roles in optimizing user experience by providing a more engaging and efficient interaction.

Shielding Against EMI/RFI Interference

Electromagnetic Interference (EMI) and Radio-Frequency Interference (RFI) can severely impact membrane switch performance by disrupting signal transmission. Shielding techniques are essential to mitigate these interferences for maintaining the integrity and functionality of the switches. Strategies include the use of conductive materials and grounding techniques to create barriers against these unwanted interferences. Industry experts emphasize the relevance of EMI/RFI shielding, especially for critical applications like medical equipment and aerospace technology, where signal reliability is paramount. Implementing such measures ensures membrane switches operate unaffected by external electromagnetic fields, aligning with industry standards for reliability and safety.

Top Membrane Switch Solutions for Diverse Applications

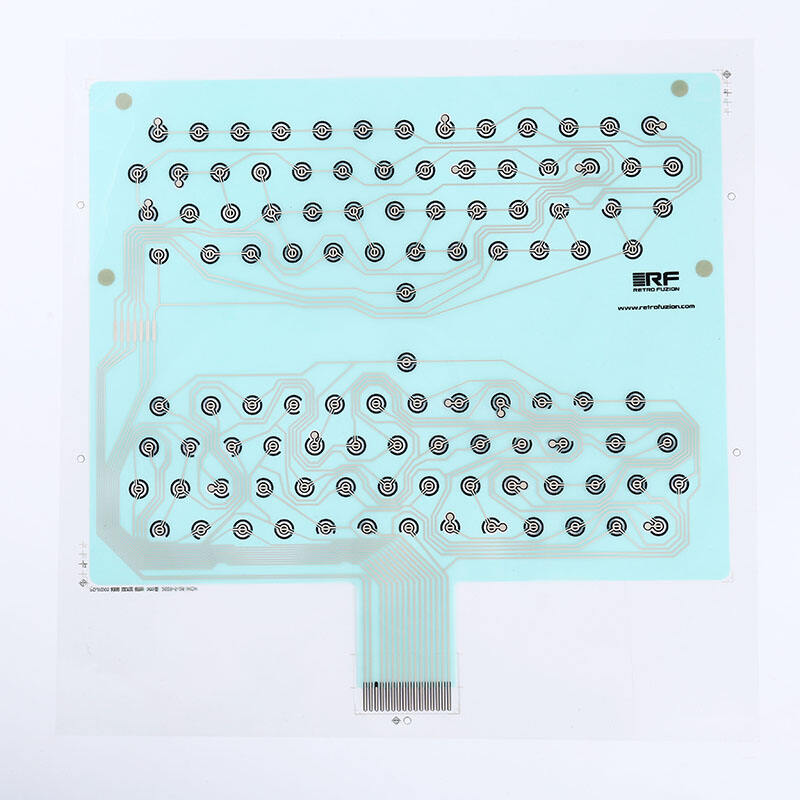

PCB Membrane Switch

PCB membrane switches are a cutting-edge evolution in switch technology, gaining popularity for their versatility in various industries. These switches combine the benefits of membrane technology with printed circuit boards to offer enhanced flexibility, robustness, and precision. Over traditional mechanical switches, PCB membrane switches provide a more compact and lightweight solution—ideal for today’s complex electronic devices that demand space efficiency. This flexibility is especially beneficial in portable electronic devices and medical equipment where space constraints are paramount.

PCB membrane switches are particularly effective in applications that require reliable and long-lasting performance. For instance, they are often used in the medical industry due to their durability under frequent usage and exposure to cleaning agents. Similarly, they find applications in the industrial sector, where they withstand harsh environments, offering a high degree of reliability. You can explore more about them with the [PCB Membrane Switch](https://www.membraneswitch-keypad.com/pcb-membrane-switch409).

Custom Backlit Membrane Switch

Custom backlit membrane switches offer aesthetic enhancements and functional benefits, particularly in user interface design. These switches integrate lighting elements like LEDs to improve visibility and engagement, especially in low-light environments. Backlighting enhances the usability of the switch, ensuring users can operate devices efficiently without straining their eyes. This feature significantly improves the user experience in aviation and automotive industries, where low-light conditions are common.

The underlying technology of backlit membrane switches involves utilizing LED, fiber optics, or electroluminescent sources, each offering unique benefits in terms of durability and energy efficiency. Backlit designs enable manufacturers to create visually striking interfaces that are not only functional but also pleasing to the eye, meeting the dual demands of form and function. Explore more with the [Custom Backlit Membrane Switch](https://www.membraneswitch-keypad.com/custom-backit-membrane-switch).

Remote Control Membrane Switch Panel

Remote control membrane switch panels are revolutionizing the home automation sector, offering unparalleled convenience and efficiency. These panels allow users to control various devices wirelessly, integrating seamlessly with smart home ecosystems. The benefits of this wireless technology are multifaceted, improving user convenience by eliminating the need for physical proximity to switches, thus allowing control of devices from different rooms or even remotely via smart devices.

In recent years, the demand for remote control panels has surged across sectors such as residential, commercial, and industrial automation. This trend mirrors the growing inclination towards smart home technologies, reflecting how modern consumers value connectivity and integration of household devices. Consequently, businesses are increasingly investing in these technologies to capitalize on user preferences for improved comfort and control. Learn more about these features at the [Remote Control Membrane Switch Panel](https://www.membraneswitch-keypad.com/remote-control-membrane-switch-panel).

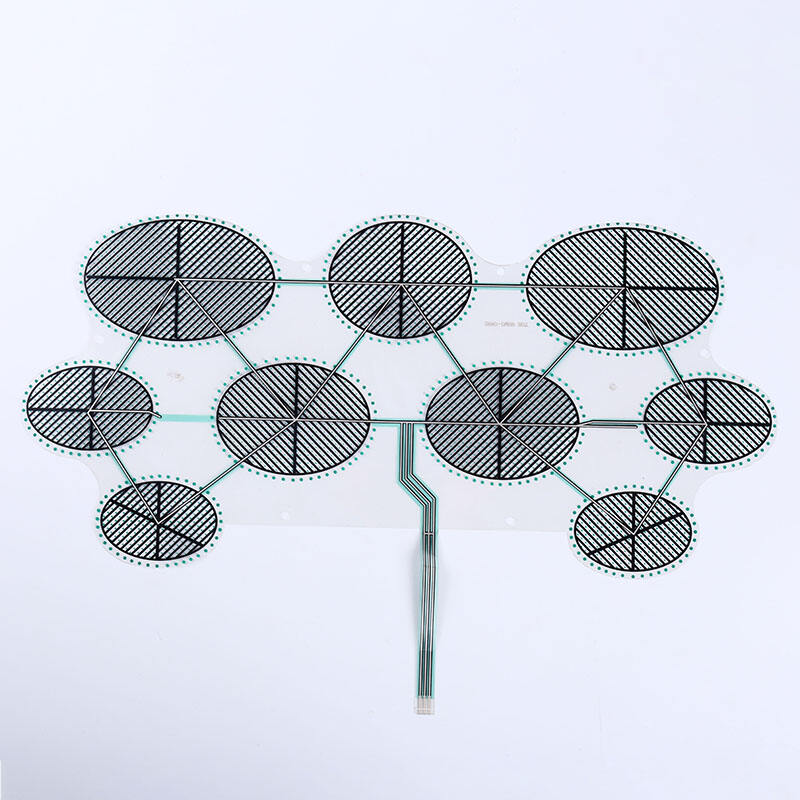

Membrane Circuit Switch (Standard)

Standard membrane circuit switches are well-suited for cost-sensitive applications, providing a reliable solution where budget constraints are a key consideration. These switches are favored for their simplicity, effectiveness, and ease of integration into various devices without compromising performance. Unlike traditional mechanical switches, membrane switches offer a slim profile with fewer components, reducing costs and maintenance.

Industries such as consumer electronics and domestic appliances commonly employ these standard switches. Their widespread usage is attributed to their ability to perform consistently under varying conditions while maintaining a cost-effective operation. Studies indicate that the use of membrane circuit switches in the manufacturing of keyboards and remote controls is increasing, thanks to their affordable and dependable nature.

Membrane Circuit Switch (High-Durability)

High-durability membrane circuit switches are engineered to withstand extreme environments and rigorous use, distinguishing them from standard versions. These switches are constructed using robust materials that resist wear and tear, making them ideal for industries like automotive, military, and aerospace applications, where durability is critical. Such industries require switches that can endure harsh conditions such as high temperatures, moisture, and physical stress without compromising performance.

According to industry reports, high-durability membrane switches significantly boost product longevity and operational efficiency. For example, their incorporation in heavy machinery has resulted in reduced downtime due to switch failures, enhancing overall operational productivity. These statistics underscore the pivotal role that high-durability membrane switches play in maintaining seamless and uninterrupted operations across challenging industrial landscapes.

Hot News

-

Membrane Switch Panel Sample Instructions

2023-12-14

-

Do You Know the Reasons Why Hot Pot Slices Cannot Pop Up When Pressed?

2023-12-14

-

What is a Light Guide? Hongmao Specializes in the Production of Light Guide Sheets, Did You Know?

2023-12-14

-

How Many Rulers Are Needed To Make A Membrane Switch?

2023-12-14

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI