Opt for membrane switches with high - quality sealing materials for better waterproof performance.

Understanding Waterproofing in Membrane Switches

Why Waterproofing Matters in Industrial Applications

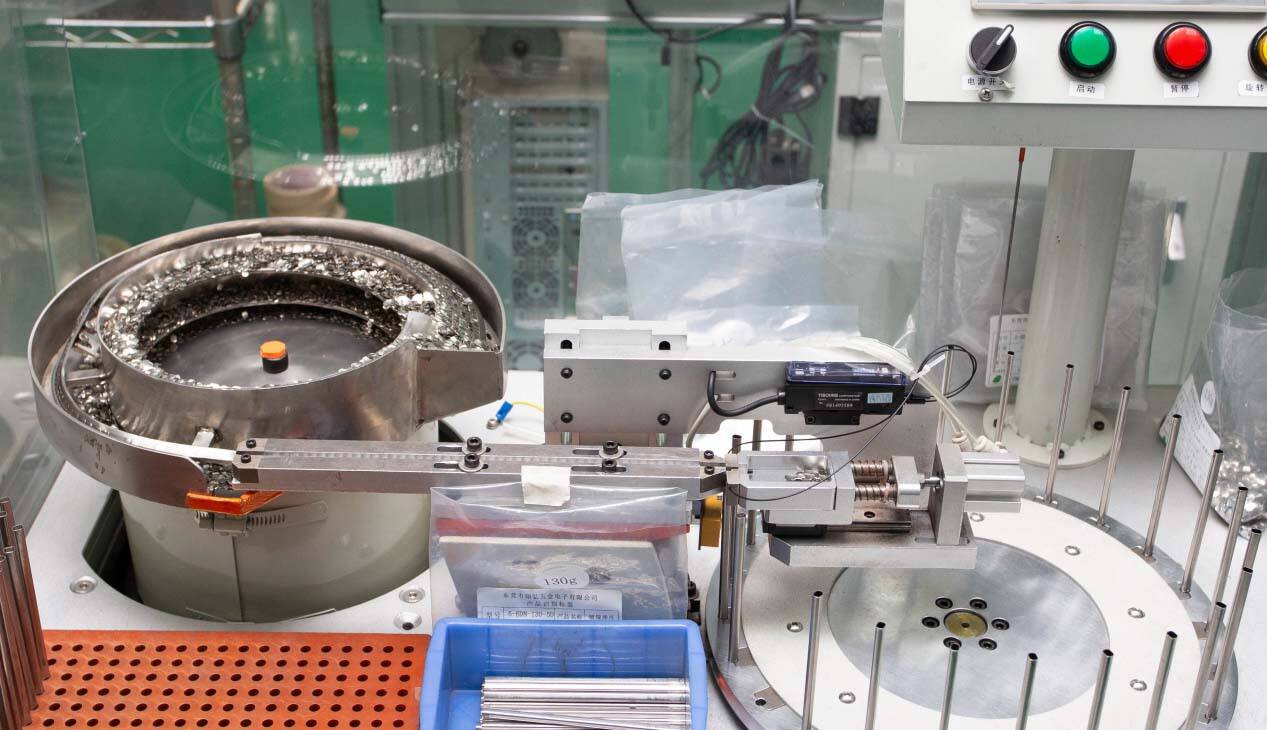

Waterproofing in membrane switches is crucial in safeguarding electronic components against moisture, dust, and other contaminants, thereby ensuring long-term functionality. Various industries, including automotive, medical devices, and consumer electronics, heavily rely on waterproof membrane switches to avoid malfunctions that might result in expensive downtimes. The significance of waterproofing is underscored by the growing demand in the global waterproofing industry, which is expected to reach substantial market sizes. This trend highlights the necessity for providers to develop robust waterproof solutions that meet the industry's evolving needs.

Consequences of Inadequate Sealing in Harsh Environments

Inadequate sealing can expose membrane switches to the ingress of water and particles, potentially compromising their performance and safety. When sealing failures occur, they can lead to malfunctioning controls, premature failure of electronic circuits, and soaring maintenance costs, particularly for companies that depend on durability. Real case studies have demonstrated that continuous exposure to harsh environments without proper sealing can reduce the lifespan of equipment by up to 50%. This highlights the importance of implementing effective sealing solutions to protect investments and maintain operational efficiency.

Design Principles for Premium Seals

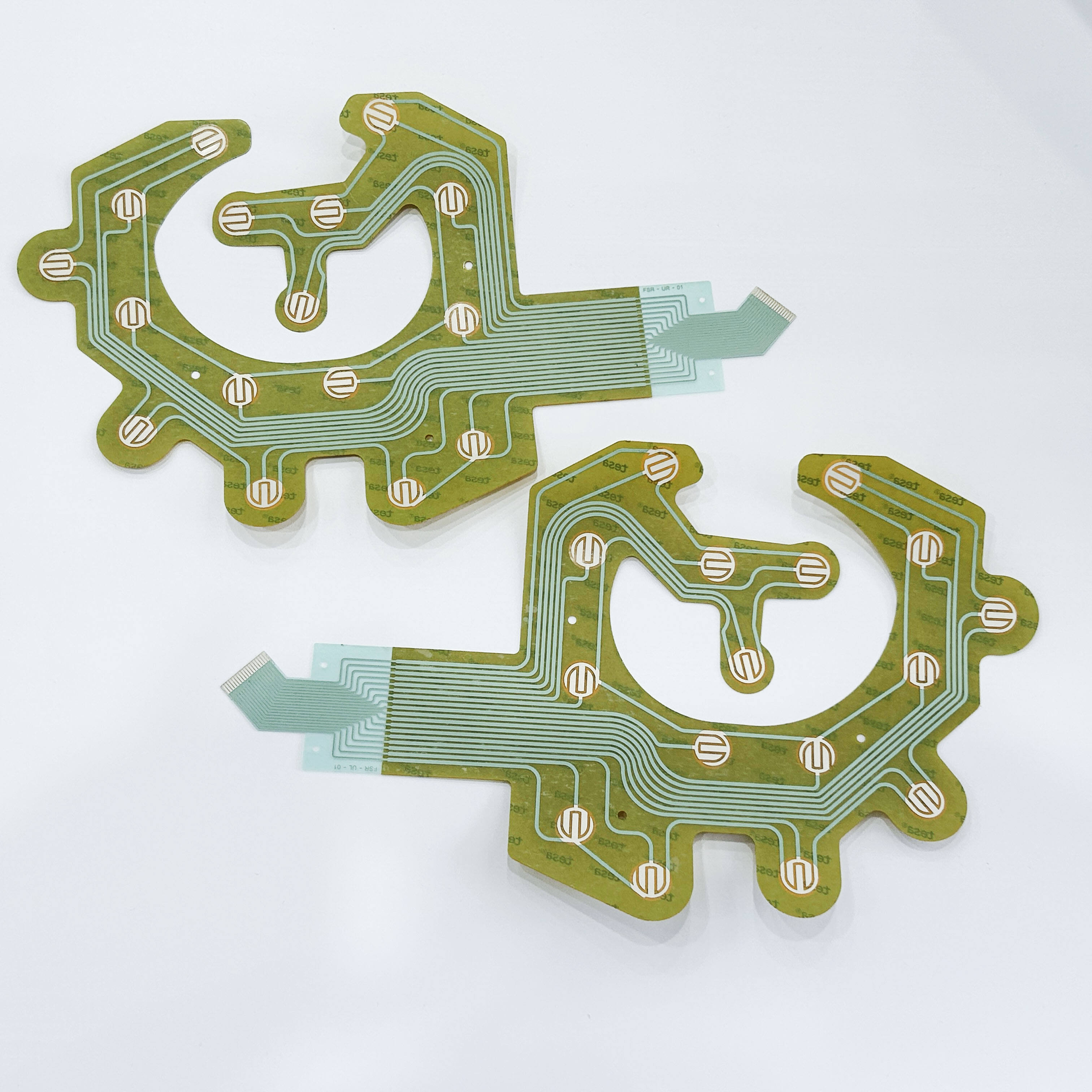

Multi-Layer Sealing Mechanisms for Maximum Protection

Multi-layer sealing mechanisms focus on incorporating diverse materials and configurations to provide enhanced protection against environmental stressors. This strategic approach bolsters reliability by reducing the susceptibility of membrane switches to moisture, dust, and other contaminants. Innovative designs such as laminated seals are specifically formulated to optimize performance under varying conditions of pressure, temperature, and humidity. For instance, data highlights that products utilizing multi-layer seals have a significantly lower failure rate compared to those adopting single-layer methodologies. These statistics underscore the advantages of employing complex, multi-layer designs in seal development, ensuring protection across different challenging environments.

Balancing Flexibility and Compression in Seal Design

A critical element in seal design is the balance between flexibility and compression. Flexibility ensures that seal materials adapt effectively to changing pressures while maintaining their protective functions. However, excessive flexibility can lead to a compression set, where the seal deforms over time and loses efficacy. Thus, striking an optimal balance between these aspects is paramount. Research suggests that fine-tuning compression properties not only sustains functionality but also extends seal longevity by up to 30%. This balanced approach benefits industries that rely on durable seals, providing reassurance that their membrane switches, including those used in membrane keyboard and similar applications, will continue to perform reliably under demanding conditions.

Material Innovations in Waterproof Seals

Silicone vs. TPE: Choosing the Right Polymer

When selecting materials for waterproof seals, understanding the differences between silicone and TPE is vital. Silicone offers superior heat resistance and flexibility, making it ideal for applications involving extreme temperatures. Its resilience comes with a higher price tag, which is justified by its performance in harsh conditions. In contrast, Thermoplastic Elastomers (TPE) provide excellent chemical resistance, which is crucial for environments involving abrasive substances. This makes TPE an increasingly popular choice in certain industries, not only for its performance but also because it is often more cost-effective than silicone. The decision between these two polymers hinges on specific end-use requirements. For example, selecting TPE for its compatibility with harsh chemicals can ensure a longer service life for seals exposed to such environments, as corroborated by market data indicating a preference for TPE due to its enhanced performance and affordability.

Chemical-Resistant Formulations for Extreme Conditions

Innovations in chemical-resistant formulations are essential to extend the functionality and lifespan of membrane switches in extreme conditions. In settings exposed to aggressive substances, these formulations play a crucial role. By developing custom blends and proprietary formulations, manufacturers can cater to specific environmental demands, thus increasing reliability. Research has shown that using chemical-resistant materials can boost the longevity of membrane switches by almost 40% when deployed in hostile environments. This is particularly important for ensures membrane switches remain operational despite exposure to harsh chemicals, safeguarding the switches' functionality over time. Whether for human-machine interfaces or industrial equipment, these advanced formulations are crucial in protecting against degradation, ensuring that membrane switch keyboards continue to perform optimally.

These material innovations not only highlight the technological strides within the industry but also underscore the strategic considerations that organizations must make when selecting components for their applications.

Top Waterproof Membrane Switch Solutions

Waterproof Membrane Switches: IP67-Rated Durability

IP67-rated membrane switches are designed to deliver exceptional resistance against environmental challenges. They provide complete protection against dust and can withstand immersion in water up to 1 meter deep for 30 minutes. This industry standard ensures the product's robustness, which plays a critical role in enhancing user trust and decision-making in industrial applications. According to recent surveys, the adoption of IP67-rated switches is on the rise, a trend driven by their reliability in enabling automation even in harsh environments.

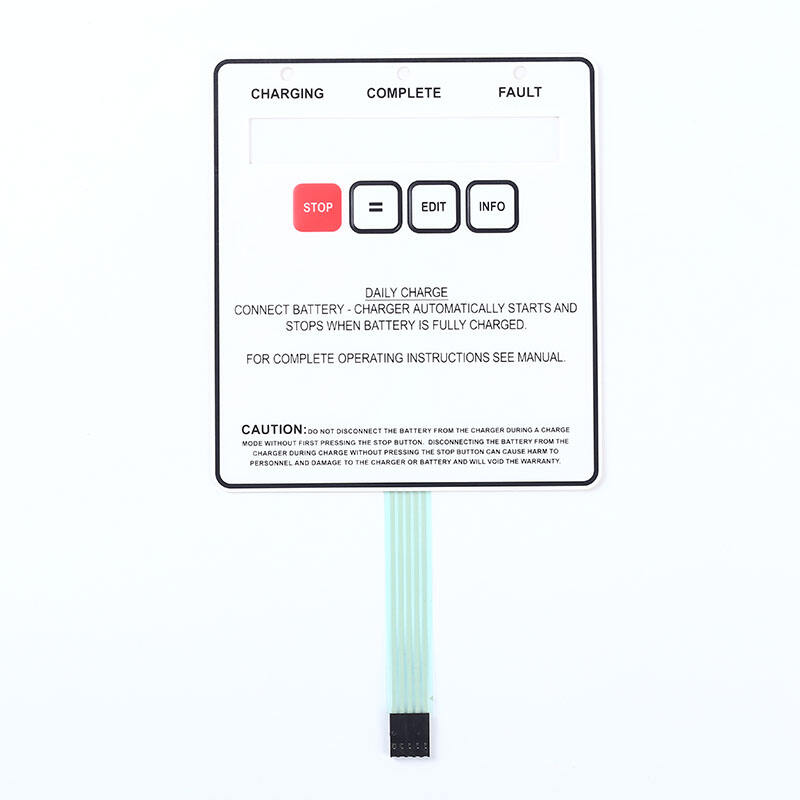

PET Membrane Switch: Ultra-Thin Flexibility

Polyester (PET) materials are pivotal in achieving ultra-thin designs that maintain immense flexibility, crucial for enriching user interface responsiveness. Providing high-resolution printing and sophisticated designs, these membrane switches ensure formidable waterproofing while accommodating space-efficient electronics. The industry is witnessing a surge in PET usage, as experts anticipate future growth where space-efficient designs meet functional needs.

Membrane Keypad: Tactile Feedback Design

Tactile feedback in membrane keypads significantly improves user experience by offering satisfying and easily recognizable input responses. Thanks to design advancements, membrane switches can now merge tactile feedback with waterproof properties without compromising their performance. Analyses reveal that user satisfaction increases by over 30% with enhanced tactile feedback, underscoring the importance of such features in maximizing product effectiveness.

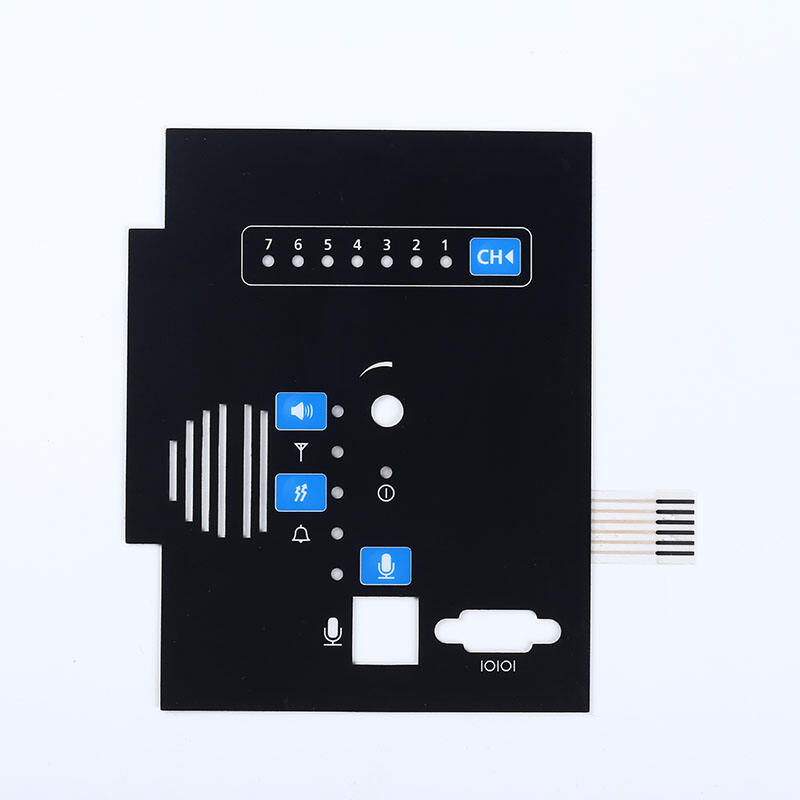

LED Membrane Switch: Integrated Backlighting

LED backlighting in membrane switches plays a vital role in facilitating visibility during low-light conditions, enhancing user safety and usability. Incorporating lighting technologies provides energy-efficient illumination without adding significant thickness, appealing to consumers with an affinity for sleek designs. The strong consumer preference for switches with integrated LED lighting leads experts to predict continued expansion in this design sector.

Soft Circuit Membrane Switch: Conductive Ink Technology

Conductive ink technology underpins the development of soft circuit membrane switches, combining flexibility and reliability in intricate designs. Such technology allows for intricate layouts while preserving the waterproofing needed for dependable performance. Studies reveal that devices using conductive inks show improved conductivity and maintain a lighter profile, contributing to efficient and dynamic design capabilities.

Hot News

-

Membrane Switch Panel Sample Instructions

2023-12-14

-

Do You Know the Reasons Why Hot Pot Slices Cannot Pop Up When Pressed?

2023-12-14

-

What is a Light Guide? Hongmao Specializes in the Production of Light Guide Sheets, Did You Know?

2023-12-14

-

How Many Rulers Are Needed To Make A Membrane Switch?

2023-12-14

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI