How to ensure your membrane switch has a long - lasting key life and stable performance?

Understanding Membrane Switches

Membrane switches are interface devices that serve as user controls in various electronic appliances. Characterized by their lightweight and compact design, they are widely utilized in everyday devices such as remote controls, microwaves, and medical equipment. Their slim profile makes them ideal for integrating into products where space and weight are critical considerations.

The operation of membrane switches is centered around an electrical circuitry system that extends beneath the surface users interact with. When a user presses a designated area of the switch, a connection is briefly established between conductive routes, completing an electric circuit. This process translates the user's physical action into a digital input that manages a device's functions.

The fundamental components of these switches include graphic overlays, touch-sensitive layers, actuation mechanisms, and substrate materials. The graphic overlays act as the interface between the user and the electronic circuitry, providing labeled areas to guide interaction. Touch-sensitive layers detect user contact, while actuation mechanisms, such as tactile domes, offer feedback to confirm button activation. Lastly, substrates form the supporting foundation, ensuring structural integrity and housing conductive elements essential for the switch's functionality.

How to Improve Membrane Switch Durability and Performance

Improving the durability and performance of membrane switches begins with selecting high-quality materials. Commonly used materials like polyester and polycarbonate are ideal due to their superior resistance to wear and tear. Polyester, for instance, is known for its robustness against scratches, while polycarbonate offers excellent durability against repeated use, making both materials popular choices for enhancing the lifespan of membrane switches in various environments.

The layer composition of membrane switches plays a vital role in their functionality and durability. Additional protective layers can be incorporated to shield internal circuits from external damage while simultaneously enhancing tactile feedback for the user. These layers ensure that the switch not only remains operational but also feels comfortable and responsive during usage. Strategic layering thus increases both the protective attributes and user experience, enabling membrane switches to perform effectively over extended periods.

Environmental resistance features, such as moisture-proofing and UV resistance, are crucial for membrane switches, particularly those used in challenging environments. According to industry statistics, failure rates can significantly decrease when these protective features are in place, effectively safeguarding against moisture penetration and UV exposure. For instance, well-protected designs with comprehensive environmental resistance exhibit lower failure rates when compared to those without, highlighting the importance of such features in extending the life and reliability of membrane switches.

Key Design Considerations for Membrane Switches

Designing membrane switch circuits involves several crucial considerations to ensure reliability and performance, especially in high-density applications. Key practices include appropriate circuit design techniques such as determining adequate trace width and spacing. Traces should have smooth, rounded corners to minimize interference and mechanical stress. Using wider traces as well can help reduce electrical resistance, ensuring the optimal current-carrying capacity for improved durability and signal integrity.

Tactile feedback significantly enhances user interaction, with variations in actuation forces directly impacting user experience and accessibility. For instance, a lower actuation force may be preferable for certain consumer electronics due to ease of use, while higher forces can offer crucial haptic feedback in industrial controls, helping to prevent accidental activation. Selecting the right tactile response tailored to application-specific requirements is key to user satisfaction.

Customization of membrane switches for specific applications is vital to optimize device performance across various sectors, including healthcare and industrial domains. Tailored designs can meet unique operational demands, such as using specific graphic overlays in medical devices to denote urgency or function-specific information. In industrial applications, ruggedized membrane switches provide resistance to harsh environments, ensuring operational efficiency and safety. By customizing switches to fit distinct application needs, manufacturers can significantly enhance functionality and user experience in specialized fields.

Choosing the Right Adhesives

Selecting the appropriate adhesives is crucial for ensuring the long-lasting performance of membrane switches. Key properties to consider include temperature resistance, adhesion strength, and chemical compatibility. Temperature resistance is vital for applications exposed to varying environmental conditions, while strong adhesion ensures the membrane switch remains securely attached throughout its lifespan. Chemical compatibility is essential for preventing deterioration when the switch encounters various chemicals or solvents common in industries such as healthcare and manufacturing.

Proper adhesive application techniques are essential for maximizing bond longevity in membrane switch assemblies. Pressure-sensitive adhesives are a popular choice due to their ease of application and strong bonding capabilities. To achieve optimal adhesion, the bonding surfaces must be clean and dry. Applying firm pressure while ensuring alignment is critical. Starting from a top corner, gradually remove the adhesive liner and apply pressure along the way. Industry standards also recommend allowing the adhesive to cure fully, which typically takes up to 72 hours. These techniques ensure the adhesive bond can withstand repeated use and environmental challenges.

Testing and Quality Assurance

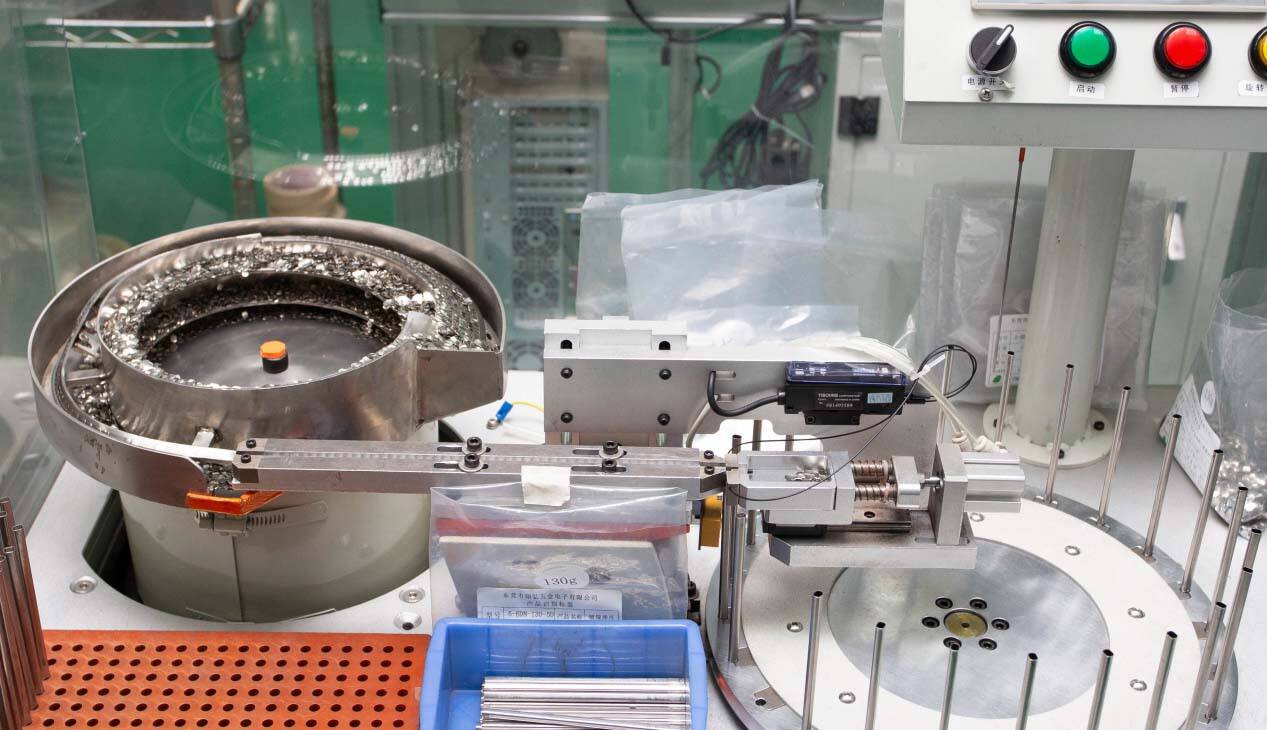

Rigorous testing and quality assurance are essential in the development of membrane switches to ensure their reliability and reduce field failures. By conducting validity and reliability assessments, manufacturers can identify potential issues before products reach consumers. These evaluations help in maintaining high product standards and ensure that membrane switches operate effectively under various conditions, ultimately minimizing customer complaints and costly returns.

Common testing protocols for membrane switches include environmental stress tests, lifecycle testing, and user compliance trials. Environmental stress tests, such as high and low-temperature assessments, simulate extreme climate conditions to evaluate performance. Lifecycle testing examines the durability of the switches over extended periods of use, while user compliance trials verify that the design meets industry standards, such as IPC-620. These comprehensive testing methods are crucial for achieving high-quality membrane switches that can endure diverse operational environments.

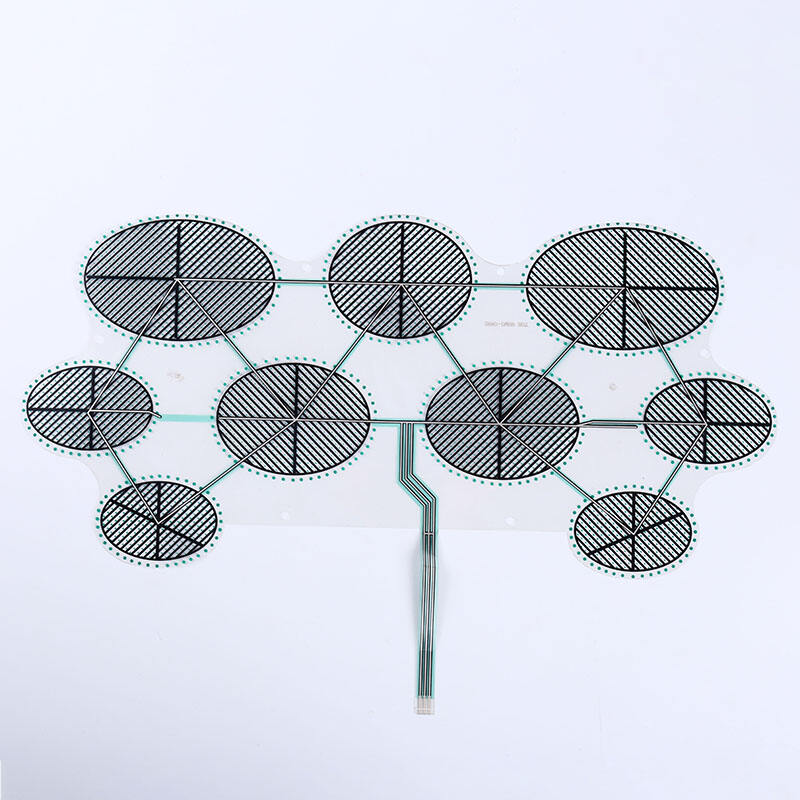

Product Highlight: Membrane Circuit Switch

Membrane circuit switches offer numerous advantages over traditional mechanical switches, making them a popular choice across various industries. These switches feature a compact design, significantly reducing the size and weight of devices, which is particularly beneficial in fields such as medical devices and consumer electronics where space is limited. Additionally, they provide a user-friendly interface with a seamless, flat surface that is easy to clean and operate, enhancing the overall user experience.

Membrane circuit switches find diverse applications across a range of industries, highlighting their versatility. For instance, in the automotive sector, they are used for dashboard controls and keypads due to their durability and resistance to harsh conditions. In the medical field, these switches are essential for devices like diagnostic equipment, where reliability and sterility are crucial. Furthermore, in consumer technology, they are used in everything from home appliances to remote controls, underlining their widespread appeal and practicality in modern electronic designs.

Hot News

-

Membrane Switch Panel Sample Instructions

2023-12-14

-

Do You Know the Reasons Why Hot Pot Slices Cannot Pop Up When Pressed?

2023-12-14

-

What is a Light Guide? Hongmao Specializes in the Production of Light Guide Sheets, Did You Know?

2023-12-14

-

How Many Rulers Are Needed To Make A Membrane Switch?

2023-12-14

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI