Copper flex circuits in membrane switches offer excellent dielectric strength and flexibility for various applications.

Understanding Copper Flex Circuits in Membrane Switch Applications

Membrane switches are essential components found in a wide range of user interfaces, playing a crucial role in consumer electronics and industrial equipment. These switches serve as the interaction point between users and devices, offering reliable and durable touch control interfaces. Industries such as medical device manufacturing, automotive, and home appliances rely on membrane switches due to their robustness and versatility, especially in environments where traditional mechanical switches may fail.

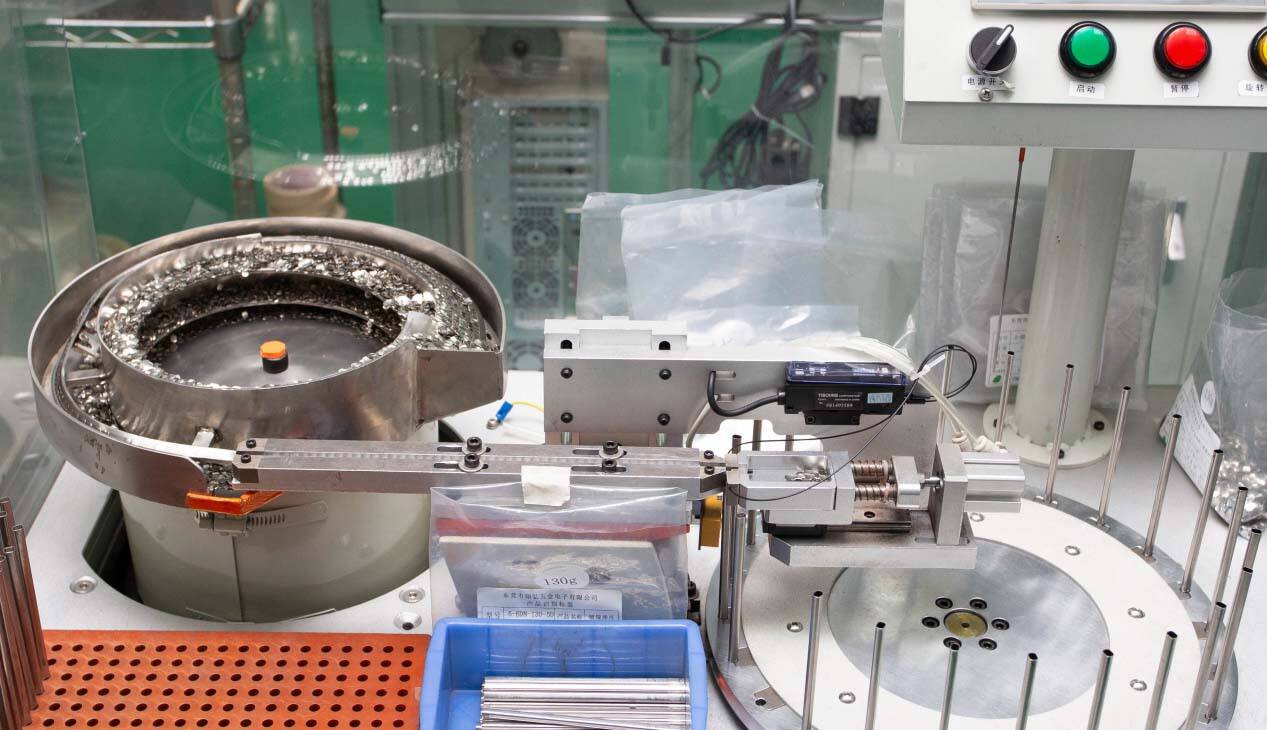

Copper flex circuits, often referred to as FPCs, are vital elements within the architecture of membrane switches. Comprising materials like polyimide or polyester substrates, these circuits host a copper foil conductive layer, crucial for touch and control functions. Copper flex circuits are preferred for their design flexibility, allowing integration in compact spaces while offering excellent electrical conductivity. This technology has steadily gained market adoption across industries due to its ability to support durable and customizable user interfaces. According to recent market statistics, the demand for FPCs in membrane switch applications continues to grow, driven by the increasing need for reliable and space-efficient design solutions.

Benefits of Copper Flex Circuits in Membrane Switches

Copper flex circuits offer significant advantages in terms of durability and flexibility over traditional materials used in membrane switches, such as silver ink circuitry. Copper flex circuits are renowned for withstanding high levels of mechanical stress and environmental hazards like extreme temperatures and moisture. Studies have shown that these circuits outperform others, offering a longer lifespan especially in demanding applications such as industrial and agricultural settings. This durability is attributed to the robust nature of copper and the advanced manufacturing processes involved.

In addition to improved durability, copper flex circuits exhibit low electrical resistance, which is essential for enhancing energy efficiency and ensuring faster response times in membrane switch applications. The superior conductivity of copper allows for efficient electrical transmission, reducing energy losses and improving the overall performance of the devices they are used in. This feature is particularly beneficial in applications requiring precision and responsiveness, such as in high-precision cardiac monitors and modern gaming consoles where quick input response is crucial. These advantages make copper flex circuits a preferred choice for advanced applications needing reliable and efficient electrical conduction.

Key Applications of Copper Flex Circuits

Copper flex circuits play a pivotal role in the consumer electronics sector, particularly in devices like smartphones and tablets. As design trends in the industry favor smaller, more efficient, and light-weight gadgets, copper's inherent flexibility and conductivity become crucial. According to industry reports, copper flex circuits allow manufacturers to design slimmer devices without sacrificing performance or durability. This makes them an ideal choice for creating the seamless touchscreens and responsive buttons that users demand in modern electronic gadgets.

In the realm of industrial equipment, copper flex circuits are indispensable for manufacturing and control panels. These environments require robust interface technologies capable of performing under harsh conditions, such as extreme temperatures or exposure to chemicals. Copper flex circuits provide the necessary durability and reliability, ensuring uninterrupted operations in these critical applications. The ability to withstand such demanding environments is essential for process efficiency and worker safety.

Medical devices also rely heavily on copper flex circuits, particularly in diagnostic tools and handheld devices. These applications demand precision and reliability, attributes that copper flex circuits offer due to their excellent conductivity and flexibility. For instance, in medical imaging equipment or portable diagnostic devices, these circuits ensure accurate data collection and processing, which is paramount for patient care.

The agricultural sector benefits as well, with copper flex circuits enhancing user interfaces in precision farming machinery. These circuits improve the functionality of control systems in agricultural equipment, facilitating better data collection and operational efficiency. Insights from agricultural technology highlight how these circuits enable farmers to execute precise planting, fertilizing, and harvesting tasks, thereby promoting sustainable farming practices. As precision farming continues to evolve, copper flex circuits are set to be a staple in agricultural advancements, offering reliability and efficiency in diverse farming environments.

Comparing Copper Flex and Traditional Circuit Technologies

When comparing copper flex circuits to silver ink circuitry, several key differences arise in terms of performance, cost, and application suitability. Copper flex circuits typically offer superior reliability and durability, which is essential in high-use environments where membrane switches or keyboard membranes are common. Industry conferences have highlighted that while copper is often more costly upfront, it provides better conductivity and greater longevity compared to silver ink circuits—ideal for applications requiring high electrical performance. On the other hand, silver ink circuits may be sufficient for simpler, low-cost applications where the durability of copper isn't necessary.

The cost implications associated with copper flex and silver ink circuits also vary significantly, particularly in terms of initial investment versus long-term savings. While copper circuits demand a higher initial cost due to material expenses, a study involving multiple case examples illustrates significant savings over time in terms of reduced maintenance and extended service life. Silver, although cheaper initially, often incurs higher long-term costs due to its susceptibility to wear and corrosion. Therefore, the choice between copper flex and silver ink can greatly influence the total cost of ownership, emphasizing the need for careful evaluation based on specific application demands. This strategic approach not only helps in managing costs but also ensures optimal performance and reliability of the membrane keypad and other related interfaces.

Products Featuring Copper Flex Circuits

Triangular Metal Dome

The Triangular Metal Dome product is specifically designed to enhance tactile feedback in membrane switches. Its unique shape allows for a more responsive touch, making it a popular choice for various membrane switch applications, such as keypads and remote controls. This design not only improves user experience but also adds to the durability and reliability of the switch.

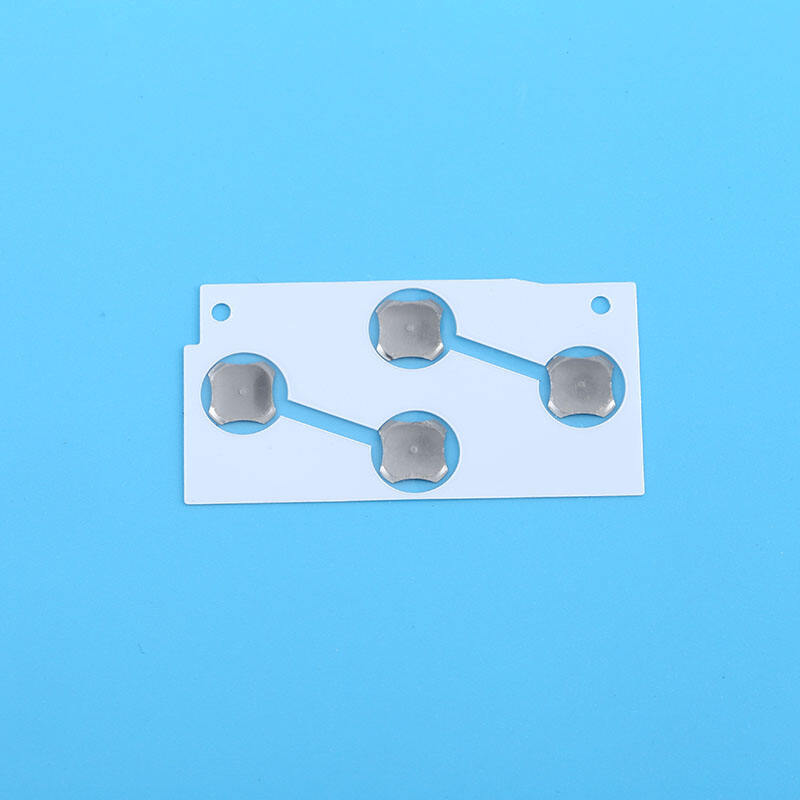

Coconut Round Metal Dome

The Coconut Round Metal Dome offers distinct application advantages across multiple scenarios, thanks to its unique round shape that ensures uniform tactile response. This product is ideal for applications where consistency in tactile feedback and user experience is critical, such as in medical devices and consumer electronics. Its versatile design makes it suitable for a wide range of uses, offering both reliability and effectiveness.

Double Dacker Structure Metal Dome Array

The Double Dacker Structure Metal Dome Array is engineered for complex user interface designs, allowing for advanced functionality and seamless integration within membrane switches. Known for its enhanced performance benefits, this product is highly effective in intricate designs requiring multiple actions. It provides both flexibility and strength, meeting the demands of more sophisticated applications in industrial controls and high-tech electronics.

Future Trends in Membrane Switch Technologies

The landscape of membrane switch technologies is evolving with advancements in flexible circuits. Notable developments include the use of cutting-edge materials and manufacturing processes designed to enhance durability and functionality. Prominent electronics firms predict that innovations such as stretchable circuits and the integration of hybrid materials will become more prevalent. These advancements aim to improve flexibility, allowing membrane switch keyboards and keypads to perform efficiently across diverse applications, including wearable technology and industrial automation.

Sustainability is also a growing focus in the production of membrane switches. Circuit manufacturers are increasingly adopting eco-friendly materials and waste reduction techniques to minimize environmental impact. These sustainable practices not only align with global environmental objectives but also cater to consumers' growing demand for environmentally responsible products. Techniques such as reducing material wastage and incorporating recyclable components are set to define the future design and production standards within the industry, ensuring that membrane switch technologies continue to be both innovative and sustainable.

Hot News

-

Membrane Switch Panel Sample Instructions

2023-12-14

-

Do You Know the Reasons Why Hot Pot Slices Cannot Pop Up When Pressed?

2023-12-14

-

What is a Light Guide? Hongmao Specializes in the Production of Light Guide Sheets, Did You Know?

2023-12-14

-

How Many Rulers Are Needed To Make A Membrane Switch?

2023-12-14

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI