5 fatores-chave a considerar ao personalizar o overlay gráfico do seu interruptor membranoso.

Entendendo Interruptores de Membrana e Seus Revestimentos Gráficos

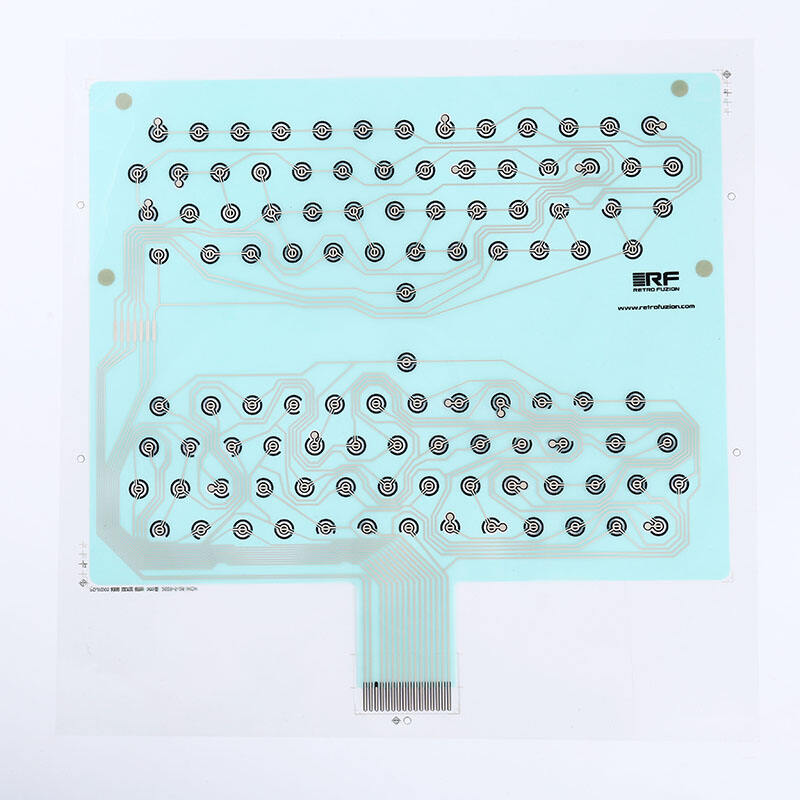

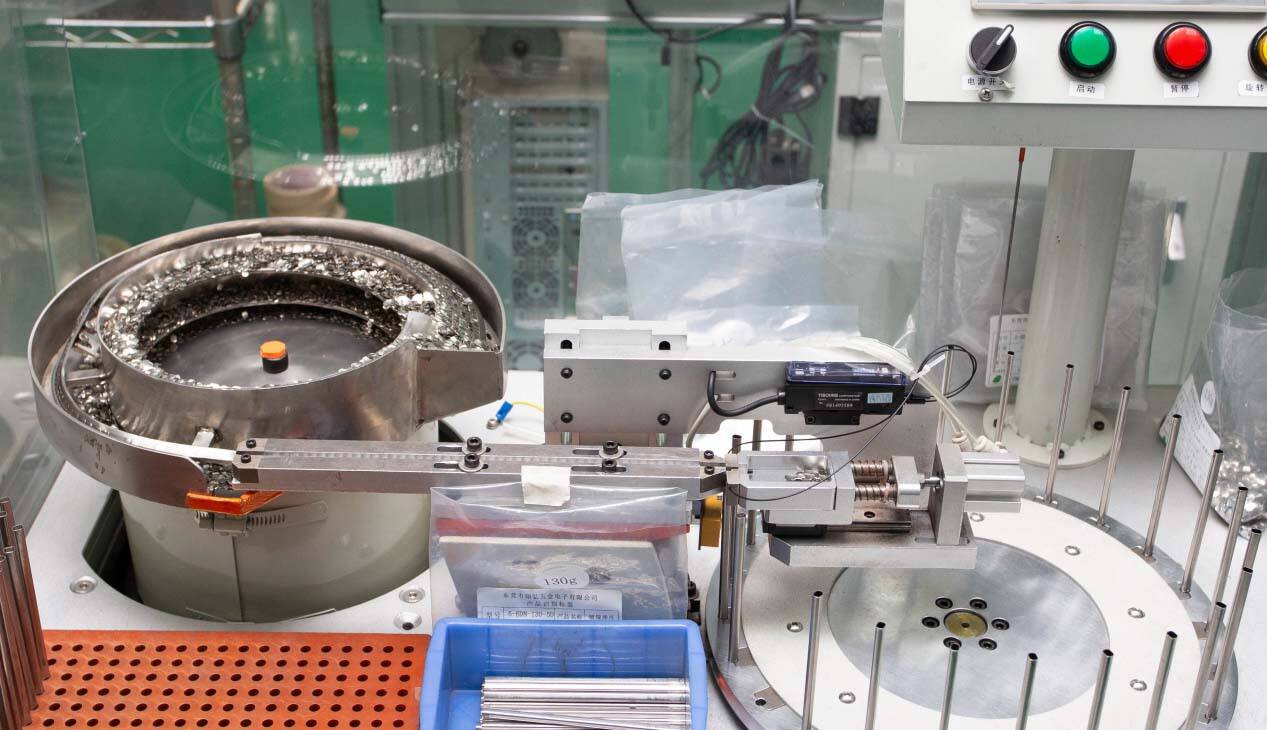

Interruptores de membrana são componentes integrantes em dispositivos eletrônicos, servindo como interfaces de usuário conhecidas por sua construção fina e flexível. Esses interruptores elétricos incorporam várias camadas, incluindo uma membrana superior, espaçador, membrana inferior e uma base, para criar uma interface tátil frequentemente usada em teclados e painéis de teclas. O mercado de interruptores de membrana está crescendo rapidamente, com uma taxa anual composta de crescimento (CAGR) projetada de 5,5% de 2024 a 2028 em vários setores, como o médico e os controles industriais, ilustrando sua utilidade e demanda crescentes.

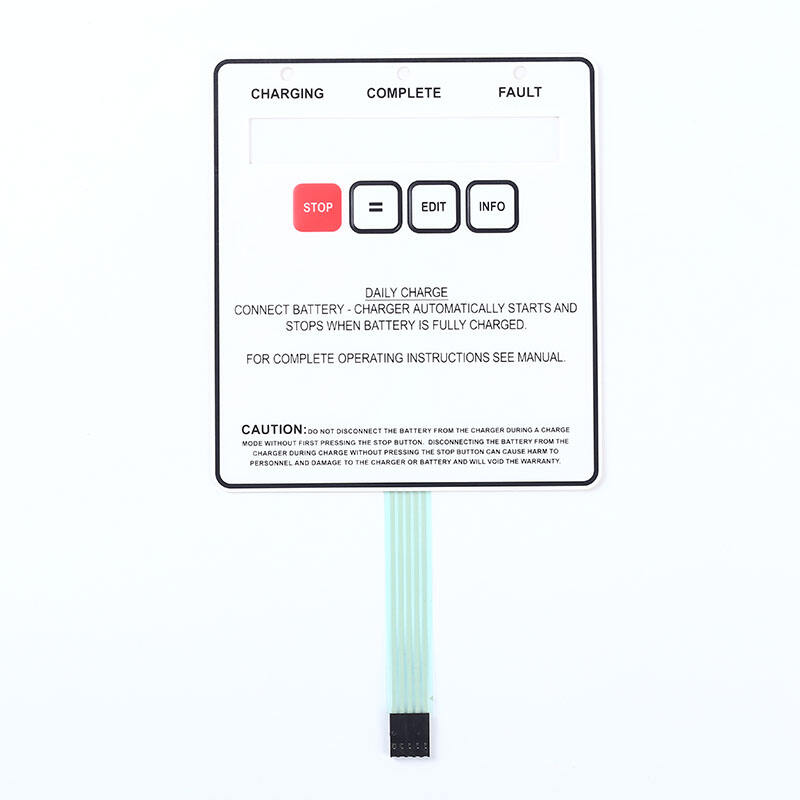

Os overlays gráficos são indispensáveis para interruptores membranos, oferecendo melhorias estéticas e funcionalidade superior. Eles contribuem significativamente para a usabilidade ao fornecerem rótulos claros, instruções e imagens de marca diretamente da superfície com a qual os usuários interagem. Os overlays gráficos também protegem contra desbotamento e desgaste, prolongando a vida útil da aparência do dispositivo e mantendo a integridade de sua marca.

A customização de interruptores membranos é crucial, pois melhora a interação do usuário e atende a necessidades funcionais específicas. Adaptar designs permite a integração de recursos como botões embossados e indicadores LED, garantindo que o dispositivo atenda a requisitos operacionais únicos e se destaque em um mercado competitivo. Essa abordagem personalizada não só melhora o engajamento do usuário, mas também aumenta a diferenciação do produto, essencial para empresas que buscam manter uma vantagem competitiva.

Fatores Chave na Customização de Overlay Gráfico para Interruptores Membranos

Ao personalizar sobreposições gráficas para interruptores de membrana, selecionar o material apropriado é fundamental para garantir durabilidade e funcionalidade. Tanto o poliéster quanto o policarbonato são escolhas populares devido às suas propriedades distintas. O poliéster oferece flexibilidade e durabilidade excepcionais, tornando-o adequado para condições ambientais severas e resistente ao desgaste e a produtos químicos. Ele é frequentemente usado em situações onde a exposição a produtos químicos e a resistência à radiação UV são cruciais. Enquanto isso, o policarbonato se destaca nas opções de personalização. Está disponível em várias espessuras e permite designs intricados devido à facilidade de corte e formação. No entanto, seu ponto fraco está na menor resistência a riscos e produtos químicos. Essas considerações são críticas para escolher o material certo com base no ambiente de aplicação pretendido.

Os aspectos de design são igualmente importantes ao personalizar sobreposições gráficas. Elementos como contraste de cor, iconografia e recursos táteis contribuem significativamente para a experiência do usuário. Um alto contraste e uma iconografia clara melhoram a legibilidade e a facilidade de uso, o que é crucial para operação eficiente em diversos ambientes. Além disso, incorporar feedback tátil por meio de recursos como botões embossados pode melhorar a interação do usuário, proporcionando uma sensação responsiva que aprimora a experiência geral do usuário. Essas escolhas de design não apenas melhoram a usabilidade, mas também conferem um apelo estético que pode diferenciar um produto no mercado.

A durabilidade e a resistência a fatores ambientais são imperativas para a longevidade de sobreposições gráficas em interruptores membranosos. A exposição à umidade, variações de temperatura e radiação UV pode deteriorar materiais ao longo do tempo, impactando o desempenho. Portanto, selecionar sobreposições que resistam a essas condições é essencial para manter a funcionalidade. Por exemplo, a excelente resistência do poliéster a extremos de temperatura e exposição à radiação UV o torna ideal para aplicações externas. Considerar esses fatores ajuda a garantir que as sobreposições não apenas suportem vários agentes estressores ambientais, mas também continuem a funcionar de forma confiável ao longo do ciclo de vida do produto.

Aspectos Técnicos das Sobreposições Gráficas Personalizadas

Compreender os aspectos técnicos das sobreposições gráficas personalizadas é crucial para otimizar o desempenho do interruptor membranoso. Técnicas de gerenciamento de cores e métodos de impressão são fundamentais, com a serigrafia e a impressão digital sendo as mais comuns. A serigrafia oferece cores vibrantes e duradouras, ideal para designs de alta contraste, enquanto a impressão digital permite gráficos intricados e casamento personalizado de cores. Cada método tem implicações na qualidade e longevidade dos overlays gráficos, afetando como eles resistem a várias condições ambientais. Por exemplo, um overlay gráfico impresso digitalmente pode oferecer flexibilidade no design enquanto mantém resistência ao desbotamento e a produtos químicos.

As técnicas de embossagem desempenham um papel pivotal no aprimoramento do feedback tátil criando superfícies elevadas que melhoram a interação do usuário. Existem vários estilos de embossing, como travesseiro e borda, que proporcionam diferentes sensações táteis. Essas técnicas ajudam os usuários a identificar botões com mais facilidade e oferecem uma sensação única ao interruptor de membrana. Botões elevados contribuem não apenas para a usabilidade da interface, mas também melhoram o design geral, tornando-os tanto funcionais quanto visualmente atraentes.

Recursos personalizados como janelas e recortes são essenciais para integrar elementos funcionais, como displays ou botões, em interruptores de membrana. Essas características permitem que componentes como LEDs ou pequenas telas sejam visíveis, impactando significativamente a usabilidade e funcionalidade do interruptor. As janelas e recortes personalizados devem ser projetados com precisão para alinhar perfeitamente com os elementos subjacentes, garantindo uma integração suave na interface. Essa customização é crucial para criar designs eficientes e intuitivos que atendam às necessidades específicas da aplicação.

Aplicações Industriais para Sobrepósitos Gráficos de Interruptores de Membrana

Interruptores de membrana são essenciais em dispositivos e equipamentos médicos, onde a confiabilidade e a conformidade são de extrema importância. Eles são frequentemente utilizados em aplicações como máquinas de diagnóstico, bombas de infusão e equipamentos cirúrgicos. Esses interruptores devem seguir rigorosos padrões de saúde, garantindo que possam resistir a processos de esterilização e uso prolongado sem comprometer a função ou a segurança. A capacidade de integrar materiais antimicrobianos aumenta ainda mais sua adequação para ambientes médicos, minimizando o risco de infecção e contaminação.

No campo da eletrônica de consumo e aplicações industriais, interruptores membranos oferecem interfaces de usuário aprimoradas por meio de sobreposições gráficas. Produtos de consumo, como controles remotos, fornos de micro-ondas e equipamentos de fitness, utilizam essas sobreposições por sua aparência moderna e interfaces amigáveis. Em ambientes industriais, painéis de máquinas aproveitam teclados membranos para fornecer controles e indicadores intuitivos. Essas aplicações se beneficiam da durabilidade e flexibilidade dos interruptores, que podem resistir a condições adversas enquanto mantêm um visual atraente.

Além disso, nos setores automotivo e aeroespacial, os designs de interruptores de membrana devem atender a requisitos únicos de durabilidade e desempenho em condições extremas. Em automóveis, eles são usados para controles no painel e ajustes de assentos, exigindo robustez contra flutuações de temperatura e vibrações. De forma semelhante, as aplicações aeroespaciais demandam interruptores para controles na cabine e sistemas de informações aos passageiros, onde a confiabilidade sob pressão e extremos de temperatura é crítica. A capacidade de personalizar esses interruptores para desafios ambientais específicos garante sua eficácia em todos esses setores exigentes.

Produtos para Interruptores de Membrana Personalizados

As teclas de membrana de PET se destacam pela sua flexibilidade e custo-benefício, tornando-as altamente adequadas para várias aplicações. Essas teclas são comumente usadas em dispositivos que exigem um equilíbrio entre desempenho e acessibilidade. Elas oferecem excelente flexibilidade, o que é crucial para aplicações que precisam resistir a uso repetido sem degradação. Além disso, as teclas de membrana de PET podem ser utilizadas em eletrônicos de consumo, sistemas automotivos e até mesmo em alguns equipamentos médicos onde robustez e confiabilidade são necessárias.

As teclas de membrana com LED trazem inovação integrando tecnologia de iluminação, o que melhora a visibilidade e a interação do usuário. Essas teclas são predominantemente usadas em ambientes onde a visibilidade é fundamental, como em painéis de controle industriais e eletrônicos de consumo especializados. A iluminação não só proporciona vantagens funcionais, mas também eleva o apelo estético, tornando essas teclas uma escolha popular para aplicações voltadas ao design.

Painéis de interruptores de membrana para controle remoto melhoram a facilidade de uso para uma variedade de funcionalidades em produtos de consumo. Esses painéis oferecem controles intuitivos e são frequentemente integrados a dispositivos de controle remoto para eletrodomésticos e aparelhos eletrônicos. Seu design foca em proporcionar uma experiência do usuário fluida e confiabilidade, que é essencial para a satisfação do consumidor e eficiência operacional.

Interruptores de circuito de membrana são projetados para suportar sistemas eletrônicos complexos que exigem interfaces compactas e eficientes. As vantagens de seu design incluem fornecer uma interface moderna além da capacidade de se ajustar a espaços restritos, tornando-os ideais para dispositivos eletrônicos avançados. Esses interruptores são utilizados em aplicações que exigem alta precisão e ocupação mínima de espaço, como controles de instrumentação e dispositivos médicos portáteis.

Melhores Práticas para o Design de Sobrepósitos de Interruptores de Membrana

Buscar assistência profissional no design de interruptores de membrana é crucial, especialmente para projetos complexos. Aproveitar a expertise de profissionais da indústria garante que todos os aspectos do design, incluindo a seleção de materiais e funcionalidade, sejam otimizados para desempenho e durabilidade. Profissionais trazem insights valiosos de projetos anteriores, ajudando a evitar armadilhas comuns e adaptar o design às necessidades específicas.

A prototipagem é uma etapa significativa no processo de design, oferecendo a chance de testar e aperfeiçoar conceitos antes da produção em larga escala. Essa prática reduz os riscos associados a falhas de design e melhora o sucesso funcional do produto final. Criando protótipos, os designers podem avaliar a interação do usuário, a durabilidade e o apelo estético dos interruptores de membrana, fazendo ajustes necessários para resultados melhores.

Incorporar um ciclo de feedback é essencial para aperfeiçoar os designs de interruptores de membrana. Coletar insights dos usuários por meio de testes de usabilidade fornece dados reais sobre como o produto se comporta em cenários de uso real. O design iterativo, com base nesse feedback, garante que o produto atenda às expectativas dos usuários e melhore a experiência do usuário. Métodos como pesquisas, grupos focais e testes beta são eficazes na coleta de valiosas entradas dos usuários que informam diretamente as melhorias no design.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI