Come identificare interruttori a membrana di alta qualità sul mercato

Comprendere gli Interruttori a Membrana di Alta Qualità

Gli interruttori a membrana sono pannelli elettrici innovativi realizzati in materiali plastici flessibili, che consentono un feedback tattile preciso al momento dell'attivazione. A differenza degli interruttori meccanici tradizionali, che si basano su numerosi componenti mobili per funzionare, gli interruttori a membrana operano attraverso un design semplificato composto da materiali stratificati, offrendo sia semplicità che durata. Questa costruzione stratificata include tipicamente un pannello, strati di circuito e un distanziatore, consentendo una trasmissione efficiente dei segnali elettrici al tocco.

Gli interruttori a membrana di alta qualità migliorano significativamente l'esperienza dell'utente e il design dell'interfaccia fornendo meccanismi di controllo fluidi e reattivi. Sono particolarmente apprezzati in applicazioni dove precisione e affidabilità sono cruciali, come dispositivi medici, macchinari industriali ed elettronica di consumo. Il funzionamento senza soluzione di continuità e intuitivo di questi interruttori aumenta la soddisfazione dell'utente e riduce la possibilità di errori operativi.

I materiali utilizzati nella produzione degli interruttori a membrana svolgono un ruolo fondamentale nel determinare le loro prestazioni e durata. Materiali di alta qualità come il poliestere e il policarbonato garantiscono che questi interruttori possano resistere a milioni di cicli di attivazione senza degradazione. Inoltre, l'uso di inchiostri conduttivi e adesivi di alta qualità ne migliora la durata, rendendoli resistenti a fattori ambientali come umidità e variazioni di temperatura. Questa attenzione alla qualità dei materiali è fondamentale per offrire interruttori che garantiscano prestazioni e affidabilità durature.

Fattori Chiave nella Selezione di Interruttori a Membrana di Alta Qualità

Quando si selezionano interruttori a membrana di alta qualità, la durabilità è fondamentale. Gli interruttori a membrana devono resistere all'usura per garantire prestazioni costanti, specialmente in ambienti impegnativi. I produttori affermano spesso che gli interruttori di alta qualità possono durare per oltre un milione di cicli. Questa lunga durata li rende ideali per applicazioni in settori come la sanità e l'automazione industriale, dove l'affidabilità è cruciale.

L'idoneità all'applicazione è un'altra considerazione chiave nella scelta degli interruttori a membrana. Ambienti diversi richiedono specifiche di design diverse. Ad esempio, le applicazioni industriali potrebbero necessitare di guarnizioni robuste e resistenza a condizioni difficili, mentre l'elettronica di consumo potrebbe dare priorità all'estetica e al feedback tattile. Abbinare il tipo di interruttore al suo ambiente operativo previsto garantisce prestazioni ottimali e longevità.

Le opzioni di personalizzazione nei pulsanti a membrana offrono vantaggi significativi, influenzando sia la funzionalità che l'appeal estetico. Personalizzando aspetti come dimensione, forma ed elementi grafici, le aziende possono allineare i pulsanti con immagini di marca specifiche o esigenze operative. La personalizzazione non solo migliora l'esperienza dell'utente, ma consente anche design innovativi che possono differenziare i prodotti in mercati competitivi.

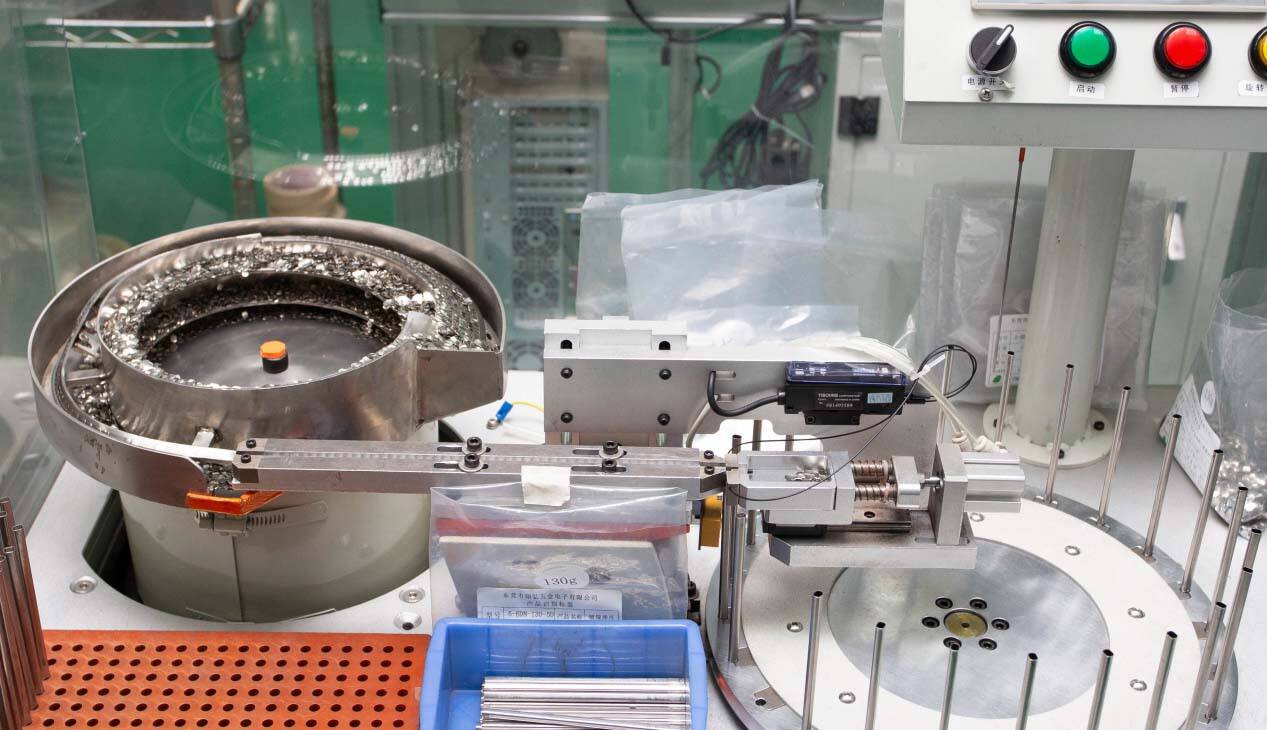

Il processo di produzione di pulsanti a membrana di alta qualità

Comprendere il processo di produzione di pulsanti a membrana di alta qualità è fondamentale per apprezzarne la durata e le prestazioni. La creazione di tali pulsanti coinvolge più strati, ognuno dei quali svolge una funzione specifica. Lo strato superiore è il sovrapposizione grafica , che funge da interfaccia visiva. È spesso realizzato con materiali durevoli come il poliestere ed è stampato con simboli e istruzioni. Sotto di esso c'è lo strato adesivo , che attacca il rivestimento al strato di circuito questo strato contiene tracce conduttive che registrano la pressione dell'interruttore ed è tipicamente realizzato con substrati flessibili come il poliestere.

Ogni strato in un interruttore a membrana svolge un ruolo cruciale. Ad esempio, lo strato adesivo non solo tiene insieme i componenti, ma garantisce anche l'isolamento elettrico. Lo strato del circuito è fondamentale per trasmettere segnali elettrici in modo affidabile. uno strato di separazione separa lo strato del circuito e l'overlay, prevenendo l'attivazione involontaria dell'interruttore a meno che non venga applicata pressione. Inoltre, materiali come inchiostri d'argento o di carbonio utilizzati nello strato del circuito migliorano la conduttività e l'affidabilità. Tutti questi componenti sono assemblati meticolosamente per fornire un'esperienza di interfaccia utente fluida ed efficiente.

Il controllo qualità è fondamentale nella produzione di interruttori a membrana, con standard come le certificazioni ISO che ne garantiscono l'affidabilità. I produttori seguono protocolli rigorosi durante ogni fase di produzione, dalla selezione dei materiali all'ispezione finale. Scenari di test robusti, inclusi test di esposizione elettrica e ambientale, aiutano a mantenere l'integrità e la funzionalità del prodotto. Tali misure di controllo qualità rigorose garantiscono che ogni interruttore a membrana soddisfi le norme del settore e funzioni in modo coerente anche in condizioni difficili, sottolineando infine il suo status di componente di alta qualità in diverse applicazioni.

Applicazioni degli Interruttori a Membrana di Alta Qualità

Gli interruttori a membrana di alta qualità sono componenti integrali in vari settori grazie alla loro versatilità e affidabilità. Nel settore industriale, trovano applicazioni nella produzione e nei sistemi di automazione, dove interfacce durevoli sono necessarie per il controllo delle macchine. Ad esempio, i pannelli di controllo complessi nelle fabbriche spesso si basano su interruttori a membrana per un funzionamento preciso e una funzionalità semplificata, resistendo a condizioni ambientali difficili.

Nel campo medico, gli interruttori a membrana sono cruciali a causa dei rigorosi requisiti di pulizia e affidabilità. Sono ampiamente utilizzati in dispositivi medici come sistemi di monitoraggio dei pazienti, pompe per infusione e altre attrezzature dove condizioni sterili e prestazioni costanti sono essenziali. La capacità degli interruttori a membrana di resistere a pulizie rigorose e la loro facilità d'uso li rendono ideali per applicazioni sanitarie.

Nei settori dell'elettronica di consumo e dell'automotive, gli interruttori a membrana sono quasi onnipresenti, dagli elettrodomestici come microonde e lavatrici, ai controlli del cruscotto delle auto. Consentono interazioni utente intuitive, garantendo che le interfacce rimangano facili da navigare per utenti di tutte le età. La loro capacità di offrire feedback tattile abbinato a personalizzazioni estetiche li rende adatti a una varietà di interfacce utente, migliorando significativamente l'esperienza dell'utente.

Tendenze future nella tecnologia degli interruttori a membrana

Con l'avanzare della tecnologia, la tecnologia degli interruttori a membrana si sta evolvendo per incorporare funzionalità più sofisticate. Una di queste tendenze è l'integrazione della tecnologia smart, comprese le capacità sensibili al tocco. Questi miglioramenti stanno rendendo gli interruttori a membrana più intuitivi e interattivi, il che avvantaggia applicazioni come l'automazione domestica e i sistemi industriali.

Inoltre, il potenziale per integrare l'Internet delle Cose (IoT) negli interruttori a membrana è significativo. La connettività IoT potrebbe consentire il monitoraggio in tempo reale e il controllo remoto dei dispositivi, aprendo nuove possibilità nell'automazione e nella raccolta dei dati in vari settori.

L'industria si sta anche spostando verso pratiche di produzione sostenibile per soddisfare la crescente consapevolezza ambientale. Questo include l'uso di materiali ecologici e l'ottimizzazione dei processi di produzione per ridurre al minimo gli sprechi e il consumo di energia. Queste pratiche non solo si allineano con gli obiettivi di sostenibilità globali, ma soddisfano anche la crescente domanda di elettronica più verde.

Conclusione

Scegliere interruttori a membrana di alta qualità è fondamentale per massimizzare le prestazioni e la longevità del tuo dispositivo. Interruttori di alta qualità non solo garantiscono una funzionalità ottimale, ma migliorano anche significativamente l'esperienza dell'utente e l'affidabilità. Ad esempio, un interruttore ben realizzato può prevenire input errati e garantire un feedback costante, il che è particolarmente importante in ambienti ad alto rischio come quelli medici o industriali. Dando priorità alla qualità nella selezione degli interruttori a membrana, puoi mitigare i rischi e migliorare l'efficienza del tuo prodotto. Assicurati di valutare la costruzione, i materiali e le considerazioni di design per prendere una decisione informata che soddisfi le esigenze specifiche della tua applicazione.

Hot News

-

Istruzioni per il campione del pannello di interruttore della membrana

2023-12-14

-

Sai le ragioni per cui le fette di vaso non possono saltare fuori quando vengono spremute?

2023-12-14

-

Hongmao è specializzata nella produzione di fogli di guida per luci, lo sapevi?

2023-12-14

-

Quanti reggenti servono per fare un cambio di membrana?

2023-12-14

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI