Founded in 2009, Company is a professional production and design of pot membrane switch,membrane switch,pot sheet,metal dome,light guide sheet,and die-cutting products of technology-based enterprises,with 15+ years of experience in the industry.

We proudly have our own factory and R&D center,and has been adhering to the development concept of "people-oriented,science and technology,quality first,service first". Insisting on the implementation of the ISO9001 quality control system and the introduction of supporting equipment in accordance with international advanced standards.

Years of R&D

experience

Sets of products

Professional

worker

Factory area

( square meters )

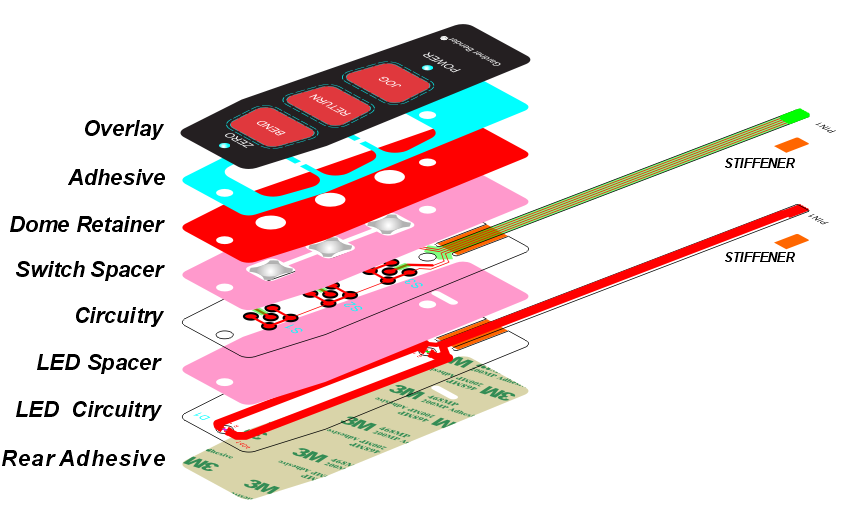

The finishing front of a membrane switch plays both a decorative and functional role. You can use gloss contrasts to highlight different interaction points on your keypad. Gloss can also play an aesthetic role to communicate your product's brand. Finish may also be coatings, for example UV resistance coating, or antistatic coating, or flamability protection layer.

You can add colour to the top layer of your membrane keypad through screen printing or through digital printing. Screen printing on foils and films ensures colour accuracy, UV resistance and abrasion resistance. The technique offers a range of possibilities including metallic colours, translucent details, RAL and PMS colours, light-blocking features, non-conductive inks. With digital printing the options are countless. You can achieve photorealistic graphics including gradients and other graphic details. Combination of screen and digital printing combines the best of both words, offering highly detailed graphics of digital print and lightproof colours of screen printing.

You can use LEDs in many different ways in a membrane switch. For decorative, functional or combined purposes. Decorative light features are usually used as deadfront effects or ghost effects where symbols are visible when lit up. Backlight is often used as a functional feature to light all keys and make them visible during night operation or operation in dark environments. Status indicators are commonly used in connection with a status window or a backlit symbol.

The most common way to create a tactile click in a membrane keypad is by using metal domes. Domes come in many different sizes, shapes and actuation forces. The choice of domes is defined by your specifications and your requirements for: the tactility - audio and haptic feedback of the key lifetime of the HMI solution. - number of activations of a key during the products lifetime.

Electrical or circuit layer in a membrane keypad is usually made with: PET - the most common and cost effective solution FPC - copper-based foil with high conductivity and bendability PCB - offering stiffness and possibility for soldering of components The choice of the most suitable circuit layer option for your keypad depends on use environment of the product, as well as the electrical and mechanical concepts of the keypad.

Metal dome packing carrier tapes product, suit for SMT production. Our Metal Domes (Tactile Dome Switch) can be packaged in tape and reel for use with automated placement equipment & machine. The metal domes are sealed in a socket on a continued tape and packed on a reel, so it can be picked and place like electronic components such as resistor, capacitor, on SMT machine. Metal domes packed in this way named as "Tape & Reel Metal Dome" Many different shapes (circle, 4-leg, cross, triangle, oblong) and forces are available. We provide wide variety of packaging options including tape and reel, plastic bottle, plastic jar & tube etc.